Electrical Panel Lockout Switches With Safety

Electrical Panel as the name suggests are the systems which distribute the units of electricity to various electricity circuits due to which the other name is given to electrical panel that is distribution board. These panels are in robust in construction, rectangular in shape and vary in sizes according to the type of system which is to be imparted in the organization. When these Electrical panel lockout are not in use from the safety point of view lockout devices are used to avoid any miss happening to take place or any accident to occur which may lead to sudden death of any individual due to electrical shocks.

The Lockout devices that are very common now days and used in many industries for the purpose of safety are being described in the information stated below.

(1) MCB (Miniature Circuit Breaker) / Circuit Breaker Lockout Device very common lockout device, prevents the circuit breaker toggle from being turned on. It is then fit with an appropriate padlock to prevent unauthorized removal.

(2) Electrical Panel Lockout Device as the name suggest device with tough, lightweight, dielectric thermoplastic bodies that completely enclose the electrical plug thus protecting against accidental reconnection.

(3) Pendant Lockout device is used to lock large electrical connectors and control the hoist.

(4) Electrical Panel Lockout is used on switches where there is no inbuilt lockout provision. They consist of removable push button and rotary switch covers, which is secured with a padlock or hasp and this cover prohibits access to a switch or control on the electrical panel. They use transparent bases and cover that allow visibility of nameplates and labels.

(5) Panel Lockout is rectangular strip which is attached to the panel cover and the rectangular strip is encapsulated by the device preventing the panel cover from being removed. The circuit breakers remain locked off while work is being done. The Panel Lockout comes with a brass padlock and reusable tagout. Panel Lockout can also be used to prevent accidental shutdowns of critical equipment by keeping unauthorized persons from accessing electrical circuit breaker panels, security panels, and data centre panels and associated pull boxes.

(6) Electrical panel lockout with square base these are covering provided on the electrical button which is spring operated, these are used to avoid accidentally pressing the button.

The Lockout Tagout Products are a great way to ensure the workplace safety of the organizations as well as the individuals. There are many world pioneers in lockout/ tagout items and administrations that offer a wide scope of strong, simple to-utilize lockout gadgets that cover most mechanical and electrical applications. Many of them cover the other basic parts of an agreeable, viable vitality control program by giving imaginative answers for preparing workers, making reported methodology, and recognizing vitality sources. Many of these devices help various kinds of organizations with restricted assets rapidly get their program up to speed, guaranteeing that lockout exercises are executed in a way that advances ideal well-being while augmenting productivity and lessening downtime.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Hasp

Enquire Now

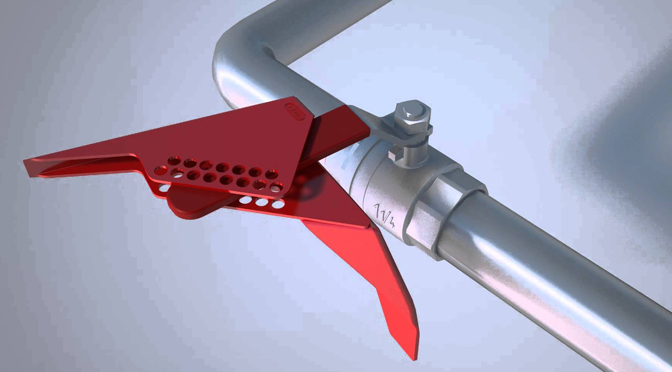

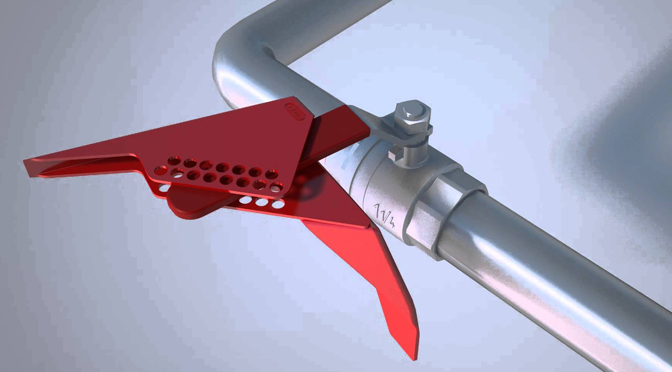

All About Ball Valve Lockout Devices

A work facility is an inexhaustible source of hazardous energy. Energy sources include electrical, hydraulic, mechanical, pneumatic, thermal, etc. and can be detrimental to work forces within the premises. A lot of industrial mishappenings around the world are caused by unexpected energy release and unanticipated equipment startup.ball valve lockout devices

A lockout safety method locks out such energy-isolating devices and ensures that they cannot be operated until the lockout device is removed. It simply aims at improving safety, maintaining compliance and encouraging sustainability. However daunting it might seem, it’s imperative that all the layers of the organization work towards implementing a sustainable lockout safety program. Without seamless cooperation, a lockout system would fall apart.

Of all the safety Lockout Tagout Products, today, we’ll discuss about Ball Valve Lockout. Ball Valve is a quarter-turn, straight-through valve that suitably transfers liquids, compressed air, clean gas and slurries (liquids with suspended solids). It uses a hollow and perforated ball to control the flow through it. The ease of operation, repair and versatility that comes with ball valves is what leads to its extensive industrial use. Ball valves have a round closure element that permits consonant sealing stress. Getting its name from the ball that rotates within to close and open the valve, these devices are used where a taut shut-off is required and are a fine source for control applications. Durable and reliable even after jagged use, these safety devices are often preferred to gate and globe valves. Ball valves involve the use of materials such as nylon, delrin, synthetic rubbers and polymers and that imparts an excellent sealing ability. However, there is a potential of wear on the seats and it renders it unsuitable for throttle applications.

Types of Ball Valves:

Valve operation in each type remains the same. The only difference is how these valves are manufactured and assembled. Each design has its own benefits.

– Split body Ball Valve

– Top entry Ball Valve

– End entry Ball Valve

– Double trunnion Ball Valve

– 3-piece Ball Valve

– Lubricated/Non-lubricated Ball Valve

Advantages that a ball valve renders:

– Smooth and straightforward actuation

– Swift opening and closing

– More compact and lighter than a gate valve

– Bubble-tight service

– Wide choices, thus allowing flexibility

– Multi-port designs

– Reliable in high-temperature and high-pressure applications

Used in a variety of applications such as gas processing and storage, fire safe protection services, chlorine manufacturing, and flowing systems, ball valves. Some typical applications are:

– Low point drains in fluid services

– High-point vents in fluid services

– Instrument root valves

– Steam service

– Feed water systems

At Lockout India, it’s all about committing to quality, performance and service. We are the leading manufacturer of various types of Ball Valve Lockout devices and our products satiate different industrial requirements and convincingly control the flow of diverse gases and fluids.

Checkout Our Other Lockout Tagout Products:

- Lockout Kit

- Group Lockout Box

- Lockout Station

Enquire Now

Keeping the work facility safe: A guide for employers

General industry workers who service and maintain the machineries are exposed to unexpected energization, startup and release of hazardous energy. The work practices can prove to be fatal if proper safety measures aren’t followed. This is where OSHA heavily focuses. OSHA’s standard 1910.147 is all about the control of hazardous energy (lockout/tagout) and requires energy control procedures for all the machines that are prone to dysfunction and could be a source of mechanical/chemical/thermal/hydraulic energy outburst.

Who has the ultimate responsibility to implement lockout safety procedure within a facility? This is perhaps the most-asked question. OSHA requires the employers to take proper steps against unexpected machinery startup and energy outbursts. But simply buying the Lockout Tagout Products is not enough. Most of the firms fall short on enabling effective procedures and fast action by employees. They do not have a set of machine-specific instructions and these instructions are generally not handy to the employees.

Follow the below mentioned steps and ensure a consistent and effective lockout safety program:

– Communication is the key: Communicate to your employees the benefits of an effective lockout program. It is your duty to instill in your employees the value of a safe working environment. Also, produce an easy-to-use set of guidelines that your employees understand.

– Make a complete list of machinery that might require lockout safety procedures. It is also important to keep your equipments in a healthy state with timely maintenance and repairs.

– Identify the energy points and label the isolation devices (valves and breaker panels).

– List and document the hardware that might be needed for to lock out and isolate machinery and equipment. Devices such as padlocks and tags.

– There’s no generic safety procedure. Make sure you document machine-specific procedures and specific steps to isolate, secure and shut it down.

– Implement comprehensive training sessions and make sure the employees have a clear understanding of safety procedures and the magnitude of hazardous energy sources within the facility.

– Sort out your workers according to their lockout responsibilities. Anyone unaware of the health hazards and safety procedure shouldn’t be allowed near the machineries but still must receive basic instructions regarding energy control. As an employer, it is your responsibility to protect all the workers.

And lastly, keep reviewing and updating your safety program. Just like machinery, a lockout safety program requires periodic reviews.

Checkout Our Other Lockout Tagout Products:

- Valve Lockout

- MCB Lockout

- Lockout Padlocks

Enquire Now