How to Use a Scaffold Tag System on Your Construction Site

Construction sites are inherently dangerous environments where worker safety must remain the top priority. Among the various safety protocols, implementing an effective scaffold tag system stands as one of the most critical measures for preventing accidents and ensuring regulatory compliance. When combined with proper lockout/tagout (LOTO) procedures, these systems create multiple layers of protection that can save lives.

Understanding Scaffold Tags and Their Importance

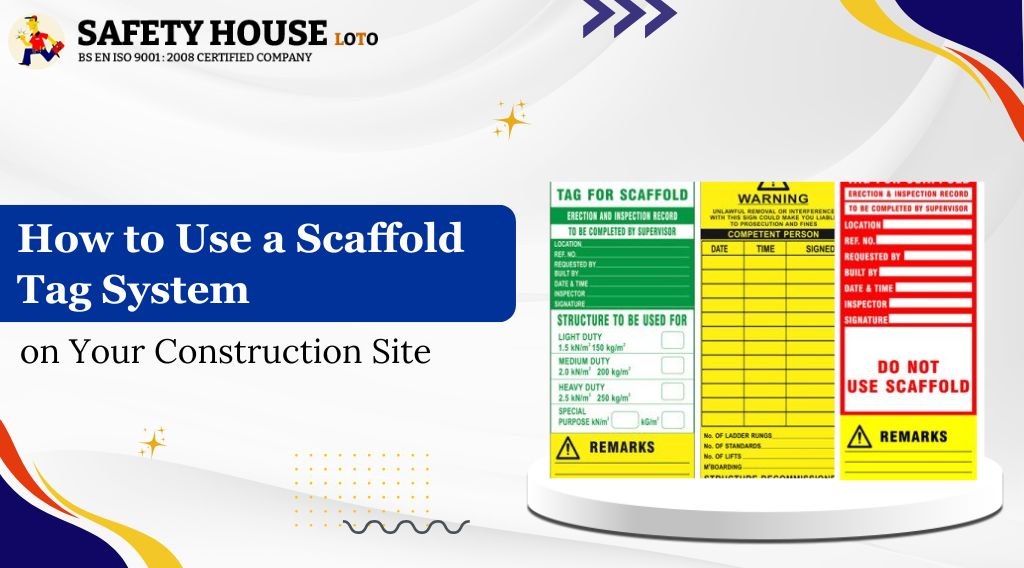

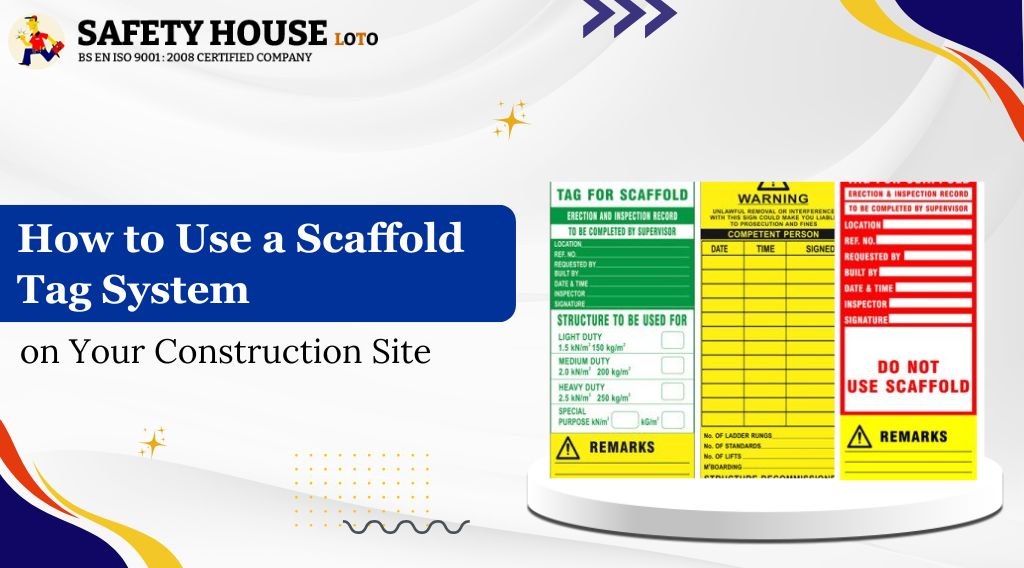

A scaffold tag serves as a visual communication tool that instantly conveys the safety status of scaffolding structures. These tags eliminate guesswork and provide clear, standardized information about whether scaffolding is safe to use, under construction, or requires maintenance. Without proper tagging systems, workers may unknowingly access unstable or incomplete scaffolding, leading to serious injuries or fatalities.

The color-coded system typically includes:

- Green tags: Scaffolding is complete and safe for use

- Yellow tags: Scaffolding is partially complete or has restrictions

- Red tags: Scaffolding is unsafe and must not be used

Essential Components of an Effective Tag System

Visual Identification Standards

Every scaffold tag must include specific information such as the inspection date, competent person’s signature, maximum load capacity, and any special restrictions. The tags should be weather-resistant and clearly visible from multiple angles. Positioning them at access points ensures no worker can enter the scaffolding area without seeing the safety status.

Documentation and Record Keeping

Maintaining detailed records of scaffold inspections, tag placements, and status changes creates an audit trail that demonstrates regulatory compliance. This documentation becomes invaluable during safety inspections and helps identify patterns that might indicate recurring issues with specific scaffolding configurations or locations.

Integration with LOTO Procedures

Lockout/tagout procedures work hand-in-hand with scaffold tagging systems to create comprehensive safety protocols. While scaffold tags indicate structural safety, a complete LOTO KIT ensures that any energy sources connected to or near the scaffolding are properly isolated and controlled.

Energy Source Management

Construction sites often have scaffolding near electrical systems, hydraulic equipment, or other energy sources. Incorporating LOTO procedures means identifying these hazards and using appropriate devices from your LOTO KIT to secure them before scaffold work begins. This dual approach addresses both structural and energy-related hazards simultaneously.

Implementation Best Practices

Training and Competency Requirements

Every worker who will interact with scaffolding must understand the tag system completely. This includes recognizing different tag colors, understanding their meanings, and knowing the proper procedures for reporting damaged or missing tags. Regular refresher training ensures these critical safety concepts remain fresh in workers’ minds.

Competent persons responsible for scaffold inspection and tagging require additional specialized training. They must understand structural engineering principles, recognize potential failure modes, and make informed decisions about scaffold safety status.

Regular Inspection Protocols

Establishing consistent inspection schedules prevents safety gaps that could lead to accidents. Daily visual inspections by qualified personnel, combined with more thorough weekly examinations, help identify issues before they become dangerous. Weather events, nearby construction activities, or equipment impacts should trigger immediate re-inspection regardless of the regular schedule.

Communication and Accountability

Clear communication channels ensure that tag status changes reach all relevant personnel quickly. When scaffolding transitions from unsafe to safe status, or vice versa, every affected worker must receive this information promptly. Digital tracking systems can supplement physical tags by providing real-time updates and maintaining automatic records.

Common Challenges and Solutions

Weather conditions, vandalism, and normal wear can damage or remove scaffold tags, creating dangerous information gaps. Regular tag maintenance and replacement protocols address these issues proactively. Having backup systems, such as digital records accessible through mobile devices, provides additional safety redundancy.

Worker compliance sometimes presents challenges, particularly when project schedules create pressure to bypass safety procedures. Strong leadership commitment to safety, combined with clear consequences for non-compliance, helps maintain consistent adherence to tagging protocols.

Conclusion

Implementing a comprehensive scaffold tag system requires commitment, training, and consistent execution, but the investment pays dividends in worker safety and regulatory compliance. When properly integrated with LOTO procedures and supported by quality safety equipment, these systems create robust protection against construction site hazards. Safety House Loto remains committed to providing the tools and expertise necessary to maintain the highest safety standards on construction sites. Remember that every tag represents a life potentially saved through proper safety communication and hazard control.