Valve Lockout Systems: Safeguarding Against Hazardous Energy Releases

In industrial settings, safety is paramount, especially when dealing with potentially hazardous energy sources. Valve lockout systems are indispensable safety lockout products designed to prevent unintended release of energy, securing the well-being of workers and minimizing the risk of accidents. In this article, we’ll explore the significance of valve lockout systems, their benefits, and how they contribute to a safer work environment.

The Role of Valve Lockout Systems in Safety

Valve lockout systems are engineered to isolate valves, preventing their operation during maintenance, repairs, or servicing. They are an essential component of any comprehensive safety lockout program and play a crucial role in safeguarding workers against unexpected energy releases. These systems are particularly effective in environments where various energy sources are present.

Understanding Valve Lockout

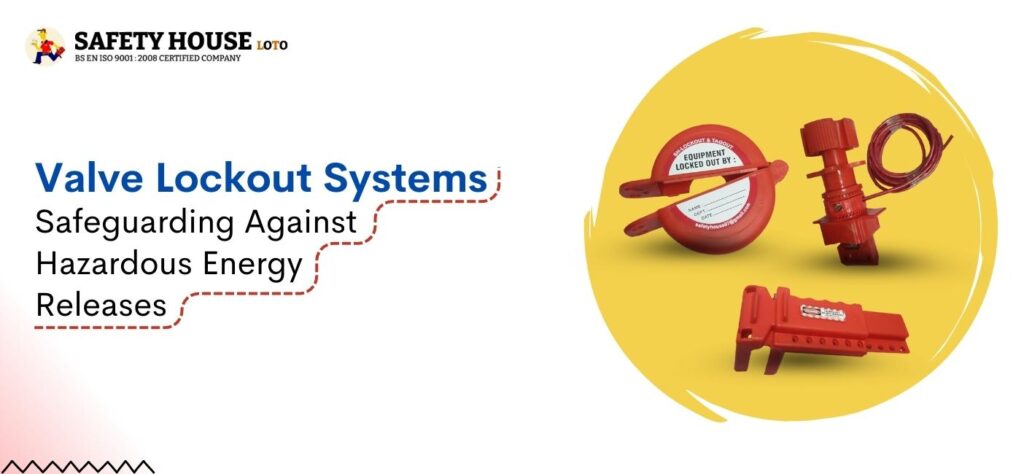

Valve lockout systems typically consist of lockout devices that fit over valve handles, preventing them from being turned or operated. These devices are often accompanied by lockout tags and labels, providing clear indications that the valve is locked out for maintenance. By immobilizing valves, these systems reduce the risk of hazardous substances, such as steam, gas, or chemicals, escaping and causing potential harm.

Benefits of Valve Lockout Systems

- Enhanced Worker Safety: Valve lockout systems provide a physical barrier that inhibits unauthorized or accidental valve operation. This minimizes the chances of workers being exposed to dangerous energy releases, contributing to a safer working environment.

- Compliance with Regulations: Implementing valve lockout systems is not only a best practice but also a legal requirement in many industries. Organizations that adhere to safety regulations, such as those outlined by OSHA, showcase their commitment to employee welfare and can avoid costly penalties.

- Versatility in Application: Valve lockout systems can be adapted for various types of valves, including ball valves, gate valves, and butterfly valves. This versatility ensures that different valve systems can be effectively locked out, regardless of their design or function.

How Valve Lockout Systems Work?

- Identification: Identify the valve to be locked out and its energy source.

- Selection: Choose the appropriate valve lockout device based on the valve type and size.

- Application: Attach the lockout device over the valve handle, immobilizing it in the off or closed position.

- Securing: Apply a lockout padlock to the device, ensuring the valve remains in the locked-out state.

- Tagging: Attach a lockout tag indicating the reason for the lockout and the responsible personnel.

Conclusion

Valve lockout systems are pivotal in maintaining a secure working environment, preventing hazardous energy releases that could lead to accidents or injuries. By implementing these safety lockout products, organizations prioritize worker safety, adhere to regulations, and create a culture of responsible energy control. Valve lockout systems stand as a testament to the commitment to safety and employee well-being in any industrial setting.

Remember, investing in quality valve lockout systems and ensuring proper training for employees on their usage is essential for the overall success of your safety lockout program.

Checkout Our Other Products:

- Loto Kit

- Lockout hasp

- Valve lockout

- Lockout station

- Lockout station