How Does Lockout Hasp Prevent You From Accidents?

Lockout hasps are designed to prevent you from accidents. Before we go into the details of how safety lockout products work to prevent accidents, let us understand the term.

When more than one employee is involved in a lockout:tagout operation, a lockout hasp plays an important role. As employees work in a group on the same energy source, the hasps allow multiple padlocks to be utilised when isolating one energy source. The lockout hasp is placed through a latch on the machinery. Each employee who is carrying out service or maintenance work attaches his padlock through any one of the six openings within the lockout hasp. All of the padlocks are then locked.

Lockout hasp has a zinc plated steel jaw so that they can pull at least 50 pounds. Sometimes, strong and spark resistant aluminium is also used in Jaws if required. Some are available with a nonconductive, red vinyl handle coating to improve the grip. It also protects the tool from scratching.

To maximise their use, Lockout Hasp also has the sign of “Danger” and “Do not Operate”. This can make them available to be used as a lockout device as well as a tag in one central unit. This ensures that each worker is working safely during the lockout operation. Various colour options in lockout hasps make them ideal for group lockout. Some lockout hasps are dual sided to lock out more than one of the equipment together.

How Lockout/Tagout Safety Can Prevent Accidents?

Working with machines requires great safety. Lockout Hasps can prevent accidents in the following way:

- Lockout Hasp does not let machines or equipment start unexpectedly. Machines may release stored energy or start by mistake which can cause harmful injuries. Safety lockout tagout products are of great use to prevent these situations.

- These lockout hasps provide efficient multi-person lockout. This means that Multiple padlocks can be applied to Loto Hasp, allowing an energy source to be isolated by more than one worker. This will ensure complete lockout and the machine can’t be operated until each worker unlocks their padlock from the hasp.

Although safety lockout products are mostly used in manufacturing companies, they can be also used in office buildings, healthcare facilities, construction sites, projects, hotels, ships, offshore installations, etc.

The good news is – it’s not an expensive proposition. Implementing an effective lockout/tagout program doesn’t require a heavy investment of time or money.

Safety House Is an ISO Certified company which manufactures products for Energy Isolation and you can trust their products for best safety.

Checkout our other safety products:

- Scaffold Tag

- Valve Lockout

- Key Box

Butterfly Lockout Device – A Complete Buying Guide

Lock devices play an important part in industries, whether it comes to giving security to the industrial warehouse or locking the flow of different gasses and chemicals. Butterfly Lockout Devices are very efficient devices helping many industries to flourish with protection.

Butterfly lockout devices are available in the market that is used in the gas, air, high-temperature service, and fire protection industry. Many agrochemicals, fluoro chemical, and base chemical industries are also using it for the good functionality and reliability of their industries.

If you are running a gas or chemical industry or providing services similar to fire protection, then you must have good quality butterfly valve lockout devices for your protection. Still, if you aren’t ready for it, here are some quick tips for finding the best butterfly lockout devices for your industry.

5 Quick Things To Check Before Buying A Butterfly Lockout Device

1] Where To Use?

Many types of butterfly valve lockout devices are available in the market, so before buying the butterfly lockout device, you must have proper knowledge of its application. The reason is that this valve lockout device is used in various appliances in industries as they use it to regulate and isolate the flow of water, gas, and air.

2] Metal Quality

Before buying any material device, you must look after its quality because it gives you an overview of the product’s life. So, it is very important to check the quality of the material before buying a butterfly valve lockout to avoid future problems like water or gas leakage from the device. As per the standard of metal quality, the device comes in various ranges, such as 201 stainless steel, 304 stainless steel, or steel, and they can be zinc plated, nickel-plated, and chrome-plated.

3] Design

Butterfly lock devices come in various ranges based on their design and use. If you have to use these locks for your home, ensure that the device meets your home’s aesthetics. But in case you are buying this valve lockout for industrial uses, then you must consider its application, whether it will be in use to control and regulate industrial gas or fuel.

4] Pressure Rating

Industries mostly use Butterfly valve lockout to regulate or isolate the flow of air, water, gas, or any other fluid. So you must check the pressure range handled by your butterfly lockout device because high-pressure fluids can harm the pipe, and it might have chances that your butterfly locking system will fail.

5] Butterfly Lock Device Valve Size

There are mainly three types of valves in the Butterfly lockout devices: concentric butterfly valves, Double-eccentric butterfly valves, and Triple-eccentric butterfly valves. You can choose among these three types of butterfly valves according to your home or industrial use.

To Wrap Up

The butterfly valve lockout device is essential for industries as well as homes for controlling the flow of fluid. In the past, this valve lockout technology was only used in oil industries, fuel handling systems, power generation, and compressed air industries. As time evolves, the device is also being used in the home door, windows, and many other things. If you are on the lookout for the best butterfly lockout supplier, you can explore our catalogs to get well-engined valve lockout devices.

Checkout Top Selling Lockout Products:

- Lockout Kit

- Lockout hasp

- MCB Lockout

- Scaffold Tag

Why Should You Choose OSHA Certified Lockout Tagout Products?

The term “lockout Tagout” refers only to the procedure to ensure that equipment is switched off and cannot be used until maintenance or repair work is complete. The safety lockout products are used to keep employees safe from equipment or machinery that could injure or kill if not handled properly.

Requirements Of An OSHA Lock Tagging:

OSHA standards set minimum requirements for controlling hazardous energy (pressure, gas, electricity, etc.). Employers must have a program to ensure that employees lock up their devices before service or maintenance. Employers must establish procedures for removing power sources from machinery and attaching appropriate equipment to prevent unexpected start-ups or recharges. It must also specify the stored energy that the machine may have. Most of the manufacturer of lockout products is OSHA certified manufacturers.

They must train employees on the projects they have established and regularly monitor procedures. An additional level of employee protection must be provided to prevent accidental injury or death of the employee.

Benefits of choosing OSHA-certified lockout tagout products:

1. Protect Workers From Dangers And Accidents:

Accidents often occur when Lockout Tagout is not taken seriously. Lockout Tagout is a life-saving device that, when used correctly in accordance with the established procedures, will protect workers from harmful emissions during servicing or maintenance machines or equipment.

2. Expressing Senior Management’s Concern For The Safety Of Employees:

Employees are an essential asset for any organization, and safety is the sole responsibility of employers such as senior management. Implementation of Proper Lockout Tagout Procedures and a successful system in the Workplace demonstrates the unprecedented commitment of senior management to their employees. Ensuring the safety and security of employees at all times is one of the employer’s greatest responsibilities. With the help of lockout supplier, the responsibility is multiplied when workers service or maintain machines and equipment that put them at risk for bodily injury or death.

3. Build Trust And Confidence Among Employees:

If the employees work in a risk-free environment, they feel empowered. The Lockout Tagout Products help all employees get home safely, and they work with confidence and feel safe.

4. Helping To Comply With Requirements:

Companies that do not recognize and control the hazards of machines are faced with regulatory fines and dire consequences. The laws involved in the Lockout Tagout process vary from country to country, as do the penalties for violations. A single event can significantly damage an organization’s reputation and prestige.

If you are interested in buying the logout Tagout products for your organization, you can choose a reliable supplier. They will provide OSHA certification for the lockout tagout product to get the best experience.

Checkout Our Products:

- Lockout Kit

- Lockout Hasp

- Scaffold Tag

- Group Lockout Box

Enquire Now

How Does Fuse Lockout Prevent You From Incidents?

What Do Fuse Lockouts Mean?

Fuse lockouts feature a unique locking mechanism that is highly visible. By doing so, the machine does not have to be accidentally taken out of the fuse block. Removing the fuse is the best way to isolate power to the electrical circuit during the maintenance work. This device helps the business owner comply with standard industrial lockout. The fuse lockout device is available in different sizes, so you can choose the right one to lock out any fuse type.

Reasons Why You Should Use Fuse Lockouts?

The fuse lockout device is designed to safeguard workers who are involved in maintenance activities. The lockout safety measure protects against unwanted equipment startup, which causes accidents. Recently, the lockout safety system has been used in different places such as industrial kitchens, bakeries, hotel laundries, etc. Unexpected activation of heavy equipment during the maintenance operation can cause a dreadful situation. Thus, employees should be aware of different machinery and their energy sources with their risks.

When To Lockout And Tagout?

As an employee, you should know when to lock out and tag out the machine. The tag offers a warning to the employee that means they don’t access the machine. The lockout protects employees by preventing the heavy equipment from being energized. Nobody can remove the device from the machine without the key. Many companies prefer lockout over tagout for the below-given reasons:

- Locks are hard to remove.

- Chemicals cannot affect the lockout device.

- They have long-lasting durability.

Different Methods To Avoid Safety Issues

There are different methods for preventing security problems, such as work permits, operation locks and temporary others. The manufacturer of lockout products uses modern technology and quality materials to offer the most excellent products for customers. You don’t allow removing the lockout during the period of shift changes. Workers attach the personal lockout during work and remove them after completing the process.

You can buy a high-quality lockout device from a leading lockout supplier and increase the security of your workspace. They not only provide special discounts on products but also deliver product quality.

Checkout Our Products:

- Loto Kit

- Osha lock

- MCB Lockout

- Valve Lockout

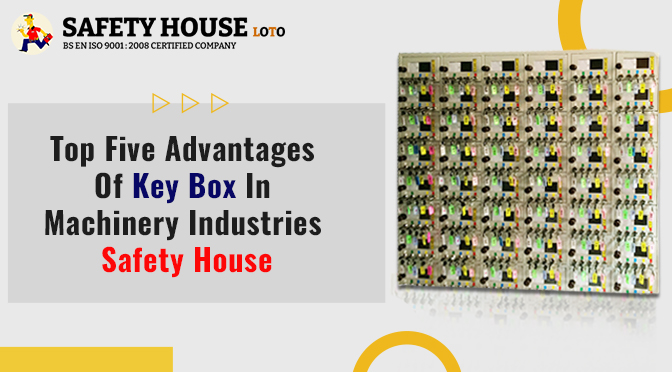

Top Five Advantages Of The Key Box In Machinery Industries

Do you need to increase security for industrial equipment? Are you seeking the best way to store keys at work safely? If yes, your solution is Key Box. It is a cabinet with many small compartments and hooks, providing employers with a better key management solution. In addition, various technicians, employees, and units use key boxes to increase the safety of expensive machinery because of its flexibility. It enables the worker to attach or remove the key of every lock without difficulty. The numerous benefits of using key boxes make them integral part in the machinery industry.

Let’s see The Outstanding Advantages Of Key Boxes Cabinet:

1. Track Keys Effortlessly

Keeping track of keys in the workspace is one of the most important advantage of key box. They should check in and out when locking machines, vehicles, rooms and equipment. On the other hand, workers can keep keys secure and well-organized through key boxes.

2. Trouble-Free Key Management

Keeping all keys secure without having to carry them is easy with key boxes. If you need to manage multiple keys, place them in a single location and mix them up. This tool’s manual key management is hassle-free, even if you have to manage hundreds of keys.

3. Organize Bunches Of Keys

If you plan to store many keys, key boxes are the most suitable choice because they have a sturdy body and plenty of hooks. It enables you to easily store large ranges of keys and organize them clearly. Besides, key boxes are fire resistant, so it is safe to hold keys without harm.

4. Offer High Transparency

Having a glass front on key boxes makes key management more accessible. Employees can access the key in their workspace without confusion. Without opening the key cabinet, the supervisor can check whether the employee has returned the machine key or not.

5. Cost-Effective

When compared to other key management methods, key boxes cabinet are budget-friendly that suits machinery industries. It provides a solid key storage solution with flexible key bars, letting you store keys in various sizes and shapes. In addition, it is an excellent option to keep the spare key protected.

You can purchase the product from a SAFETY HOUSE LOTO, if you want to use your company’s key boxes. They provide various lockout products such as key boxes, lockout station group boxes, key cabinets, and much more. All products are constructed based on the industry standard to get the quality lockout product for your business.

What Is The Purpose Of A Mini Lockout Station?

When it comes to executing the lockout program in a facility then the Mini Lockout Station is one of the most easiest and effective ways. It is a place where you can easily store all the different components of the lockout program so that they are easily available whenever required.

It is important to know that the mini lockout station also makes it easy for the employees to return everything to where it belongs so that it is not damaged or misplaced.

Lockout Tagout Products are mainly designed to be a great reminder to all staff to lock out before starting work on any machine that makes use of energy. The main purpose of a mini lockout station is to make the availability of isolation equipment hassle-free for all.

What All Comes In A Lockout Station?

There are different types of lockout stations that you can buy and each of the stations comes with a different list of items. However, generally, you will find the following items in a lockout station:

- Locks

- Tags

- Keys

- Instructions

- A location where it can be stored

The locks might be the standard padlock options or an option that can be utilized for securing a power source. Some stations come with multiple items that serve to lock out a power source so that it can be utilized on diverse types of machinery.

For the tags, a station needs to have one type of tag, or multiple types, if obligatory. Most facilities like to stick with one standard tag throughout the entire area, but this is not needed.

Purpose of Mini Lockout Station

Devices like lockout station are vital because they work as barrier guard or guarding device that is installed on any system in order to assure the safety of workers while operating such systems.

Mini lockout station assures improved protection of workers and is installed to decrease the injury of workers or exposure to any kind of accidental release of energy.

You need to know this action is taken at the time of non-routine activities like repair or set-up, maintenance, removal of misaligned feeds, jams, or clogs. The use of a lockout station is one of the foremost ways suggested to the workers in order to decrease the risk of any harm in various cases.

However, if you are looking for a perfect mini lockout station to install in your facility then make sure to reach a reliable lockout supplier that offers mini lockout stations for different purposes.

Therefore, to ensure the safety of your employees at the workplace, it is important to install a mini lockout station.

Top Selling Safety House Lockout Tagout Devices:

- Valve Lockout

- Osha Lock

- Lockout Kit

Everything You Need to Know About the Types of Circuit Breaker Lockout

You’ve probably seen Miniature Circuit Breaker Lockout (MCBs) in your home. When you turn on or off an appliance, the power of the whole floor is impacted. It is because the MCB Lockout is linked to all the circuits on the floor, and shutting off the main switch turns out the lights.

However, a circuit breaker’s primary function is to safeguard the device and humans from harmful electrical shocks and failures. Circuit breakers, in other words, are devices that prevent electrical short-circuits and sustain power flow.

Do you know anything about the circuit breaker lockout device? Do you want to discover its benefits and drawbacks? Then this article will assist you in comprehending several types of productive effects. Let’s have a look at circuit breakers.

What exactly is a circuit breaker?

Circuit breaker trips cut electricity to the load and prevent damage. Industries, buildings, commercial complexes, and hotels rely heavily on circuit breakers to convert between different modes of operation.

Why is a circuit breaker required?

Several unusual circumstances in our electrical system can harm the circuit and its components. These are referred to as ‘FAULTS.’ Furthermore, faults are classified as follows:

- Overload

- Earth Short Circuit

Besides, we must safeguard our system from the errors above to maintain our electrical components and system safe. It necessitates the use of a circuit breaker.

Types of Circuit Breaker Lockout

Circuit breakers are primarily classified according to voltage application:

1) Circuit Breaker with Low Voltage

2) Circuit Breakers for Medium Voltage

3) Circuit Breakers SF6/VACUUM

4) Circuit Breakers for High Voltage

How do they work?

Circuit breakers are built to tolerate a transient surge in amperage over their rated capability, allowing fan motors or compressors to operate. Moreover, a Time/Amperage or “Trip” curve indicates the period they can let this inrush against the actual amperage capacity they can tolerate during that time.

Read More: Circuit Breaker Lockout Device: Advantages and Disadvantages

Furthermore, depending on the breaker’s design and function, it may take up to 15 times the expected load and trip anywhere between milliseconds and 2-3 seconds later.

Breakers are classified into three positions:

- Closed circuit — on

- A trip—open circuit signals a problem as well.

- Off—short circuit

Conclusion

This overview of panelboards and several kinds of circuit breakers, their construction and operation, and fundamental electrical safety protocols is an excellent place to start if you’re new to the sector. Hence, check out Safety House blogs for a more in-depth look at these topics. In the nation, there are various lockout-Tagout service providers.

However, not all of them provide their consumers with high-quality goods. Safety House is a trustworthy business that has served its many satisfied consumers for years. Pick the best Lockout Tagout Products and Loto service provider for your company by carefully considering your requirements.

Top Selling Safety House Lockout Tagout Devices

> Key Box

> Valve Lockout

> Osha Lock

Related Post To Read: How to Ensure Worker’s Safety From Lockout Tagout Procedure?

Related Post To Read: Lockout Tagout Advantages & Disadvantages

How To Find The Lockout Padlocks As Per OSHA Standards?

When it comes to the potential of one employee mistakenly restarting a piece of equipment that another employee is working on, the employee’s sole safeguard is their lockout lock. Employees must learn how to operate their locks correctly and never give out their lock or key to guarantee complete control.

OSHA’s Lockout Tagout Regulations (1910.147)

Lockout Tagout devices must be robust, standardised, significant, and recognisable, according to OSHA Standard 29 CFR 1910.147.

- To achieve OSHA regulations, Lockout Safety Padlocks must meet the following requirements:

- Be able to tolerate long-term exposure to harsh weather conditions and be chemically resistant.

- Have a consistent color, shape, or size across the institution.

- Non-reusable, hand-attachable, self-locking, and non-releasable with a minimum unlocking strength.

- Use the tools to identify people and other recognizable data such as padlock numbers, metal marking, logos, department designations, etc.

Read more: Elements Of OSHA’s Lockout-Tagout Standard

A lockout programme consists of three key components

- Written Procedures: These protocols tell lockout participants what to do and when. They also outline the procedures for shutting down, isolating, and imposing and removing lockout. Such methods are only required for machines with two or more energy sources.

You should clearly state the following points:

- Specific machinery and their shutdown/isolation procedures

- Location of lockout mechanisms

- How to de-energize stored energy

- How isolation must confirm.

- Training Programs: Training is required for two types of employees: authorised and affected. Authorised employees maintain and service machines and are qualified to control hazardous energies. In contrast, affected employees work near the machines/equipment being serviced or repaired under lockout and must understand the hazards.

- Periodic Audits: Periodic audits ensure that energy control operations are still being done correctly, that employees are following protocols, and that they know their commitments.

What You Should Look In Lockout Padlocks & Its Benefits

Lockout Padlocks prevent mishaps by preventing equipment from being mistakenly turned on. This also prevents damage to the equipment and makes the workplace safer for everyone. Moreover, lockout Osha Lock is available in a variety of colors and is very durable, making them an excellent investment for any company.

As previously noted, are an essential component of any safety program. Workers may use Lockout Padlocks to ensure that machinery or equipment is not switched on while doing maintenance and repairs.

Safety house Lockout Padlocks may also be used to protect electrical panels, valves, and other potentially dangerous items. You may assist avoid accidents and injuries by clearly identifying dangers and shutting them out.

- Lockout padlocks are color-coded to make them easier to identify, and each Lockout Padlock may be allocated to a single employee. This guarantees that the equipment is only accessible to authorized employees.

- Padlocks, when utilized appropriately, may help make your workplace safer for everyone.

- It is a low-cost and easy approach to safeguarding the safety of your employees. Among the advantages are:

- Preventing mishaps by preventing equipment from being mistakenly turned on during maintenance.

- Disabling damaged equipment also protects it from additional harm.

- Lockout Padlocks are also useful for determining who has disabled the equipment since they are generally color-coded.

- This is significant because it makes everyone’s workplace safer.

Lockout Padlocks and Lockout Kits are a simple and efficient approach to increasing workplace safety and should be utilized wherever equipment is a danger of harm.

Conclusion

If hazardous energy is not appropriately managed workers doing regular machinery or process equipment maintenance may be badly hurt. It is why safety lockout tagout padlocks are used to turn off possible energy risks and avoid such mishaps.

To purchase the best lockout products as per OSHA standards contact the Lockout Supplier Safety House Loto.

You May Also Like: How to Ensure Worker’s Safety From Lockout Tagout Procedure?

You May Also Like: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

How Many Types of Group Lockout Box?

Loto Group Box physically locks the complete system such as the machine, equipment, and even process in the safe mode. Lockout and Tagout is the Control of Hazardous Energy which involves with isolation of energy from the system.

What is the Benefit of Group Lockout Boxes?

The Group Lockout Boxes are storage devices used to capture keys to make effective lockout of large equipment. Moreover, all the lockout is enabled with a single padlock to secure the equipment.

Lockout devices offer the best way to easily secure the machinery equipment. These have circuit breaker lockout along with the electrical plug lockout device.

The Use of Group Lockout Box keeps all the keys safely and is enabled with the safe key storage facility. All the lockout points on Loto Box are also easily accessible.

Types of Loto Group Lockout Box

These are storage devices that can be used to capture keys for effective lockout of equipment. These lockout tagout products are certified raw materials used, so they would enhance the functionality. The lockout point on equipment is secured with a single padlock.

Master Lock Group Lock Boxes S600 Series

Normally, the Master Lock Group Lock Boxes S600 Series have 430-grade stainless steel. These can easily withstand the harshest environments as they have a tough structure with superior design features.

It makes lock boxes stronger and easier to use. The Master Lock Group Lock Boxes S600 Series has a stackable design suitable for storage. It also helps with making quick transporting of multiple boxes.

Portable Red Group Lockout Box

The Master Lock Portable Red Group Lockout Boxes are suitable for capturing the keys from lockout points. It is easier to secure a lockout point even with a single piece of equipment.

Group Boxes and Loto Kits Capture keys from lockout points and easily place them in the lockbox. The Lockout Boxes are suitable for the padlock or other fixed devices.

However, it offers flexibility for the lock. This easy-to-grip is perfect for wide areas like machinery, the safety of workers, and other equipment. Read More: Advantages & Disadvantages of Lockout Tagout

Lockout Safety Heavy Duty Lockout Box

The Lockout Safety Heavy Duty Safety Lockout Boxes provide durability as well as flexibility, ensuring better access for all parties.

Furthermore, safety Lockout Boxes are also perfect for group lockout situations. All the keys have identification tags with multiple boxes under control.

Lockout Safety Portable Red Group Box

The Group Lockout Box model ensures the machine or keys in the machine are fully secure. Moreover, it accommodates up to 7 safety locks with easy to carry around. Group Lockout Box offers the best way to lock all the parts in the machine.

You May Also Like: What is an Electrical Panel Lockout Box and Its Uses?

You May Also Like: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

What are Lockout Key Box and Its Uses?

The lockout key box is the best storage device that is effectively useful to store keys for an effective lockout for huge equipment. One can protect the lockout point available on the equipment with a single padlock.

It can ensure that other technicians or departments could never remove keys, documentation, permits, or anything else before the parties open individual locks.

Safety Impact of lockout key box

Here workers can keep their keys in this box, and then only authorized employees have access to touch it. Employees can remove the personal padlock from the lock box when the work is completed and free the keys.

Read More: How to Ensure Worker’s Safety From Lockout Tagout Procedure?

However, the lockout key box can ensure that keys never be accessed until the final lock is removed.

A lockout key box is the safest approach enforced by putting the suitable lockout devices into energy-isolating devices based on the established procedure.

Furthermore, it will ensure that no one can operate the controlled equipment and energy-isolating device until removing the lockout device.

Uses of lockout key box

Lockout key boxes are handy for safe key storage and the best place for holding keys. Lockout products are highly useful in protecting employees from dangerous energy sources on equipment and machines during maintenance service.

Additionally, most industrial accidents are due to the unexpected start-up of equipment and machines or the uncontrolled release of energy. Therefore, it is better to use a high-quality lockout key box without hesitation to stop issues.

The best energy control program

Best Lockout Kit is effectively suitable for various energy control programs. An excellent energy control program contains:

- Durable, reliable, and high-quality lockout products to cover all electrical and mechanical applications

- A specially designed lockout solution can help implement and develop the control program effectively

- Documented, tailored, and appropriated lockout procedures are all OSHA complaints

- Conduct the lockout audit regularly to ensure safety in the workplace

Benefits of lockout key box

You can explore more benefits after using lockout kits. Check out below to know the benefits:

- Protect employees from accidents and hazards

- Shows top management concern over the employee safety

- Protects machine, equipment, and workplace from severe damage and reduces downtime

- Helpful in meeting the key box compliance without any issues

- Builds trust and self-confidence in all employees

Final verdict

You have now explored the lockout key box and its uses from the scenario mentioned above. You can contact the leading experts and manufacturers if you want quality lockout key cabinets.

Moreover, safety House is the leading manufacturer and lockout supplier of lockout tagout products. The lockout key boxes are powder coated, highly durable, and have stainless steel handles.

You May Also Like: What Are The 6 Steps Of Lockout Tagout Programs?

You May Also Like: Safety Precautions While Working Around the Lockout/Tagout Equipment