Lockout Kit Maintenance: Tips for Keeping Your Tools in Top Shape

Essential Tips for Maintaining Your Lockout Kit

Introduction:

A lockout kit serves as a cornerstone of safety protocols in industrial environments, providing essential tools for controlling hazardous energy sources during maintenance or repair tasks. However, ensuring the effectiveness of these kits requires regular maintenance and upkeep. In this article, we’ll explore the importance of lockout kit maintenance and provide valuable tips for keeping your tools in top shape, enhancing workplace safety and compliance.

Understanding Lockout Kits:

Before delving into maintenance tips, let’s first understand what comprises a lockout kit. Typically, a lockout kit contains a variety of devices and accessories designed to isolate energy sources and prevent the accidental or unauthorized startup of machinery or equipment. Common components include padlocks, lockout hasps, tags, circuit breaker lockouts, valve lockouts, and other specialized devices tailored to different types of energy sources.

The Importance of Lockout Kit Maintenance:

Lockout kit maintenance is vital for ensuring the reliability and effectiveness of safety measures in the workplace. Regular upkeep helps identify and address issues such as damaged or worn-out components, ensuring that lockout devices function as intended when needed. By maintaining lockout kits in optimal condition, businesses can minimize the risk of accidents, protect workers, and maintain compliance with regulatory standards.

Tips for Lockout Kit Maintenance:

- Regular Inspections: Conduct periodic inspections of lockout kits to check for signs of damage, wear, or corrosion. Inspect each component thoroughly, paying attention to padlocks, hasps, tags, and lockout devices for any defects or malfunctioning parts.

- Replace Worn-Out Components: Replace any worn-out or damaged components promptly to ensure the integrity of the lockout kit. This includes replacing padlocks with broken shackles, worn-out tags, or damaged lockout devices to maintain effectiveness and reliability.

- Clean and Lubricate: Clean lockout devices regularly to remove dirt, debris, or contaminants that may impair their functionality. Apply lubricants to moving parts such as hinges and locking mechanisms to ensure smooth operation and longevity.

- Store Properly: Proper storage is essential to prevent damage and prolong the lifespan of lockout kits. Store kits in designated areas away from harsh environmental conditions, extreme temperatures, moisture, or direct sunlight.

- Update and Expand: Periodically review and update lockout kits to ensure they remain relevant and effective for the equipment and energy sources present in the workplace. Consider expanding kits to accommodate new machinery or equipment additions.

- Employee Training: Provide comprehensive training to employees on proper lockout kit maintenance procedures. Educate workers on the importance of inspecting, cleaning, and replacing components as part of their safety responsibilities.

- Document Maintenance Activities: Maintain detailed records of lockout kit maintenance activities, including inspection dates, component replacements, and any issues identified and addressed. Documentation helps track maintenance history and ensures accountability.

- Seek Professional Assistance: If unsure about maintenance procedures or encountering complex issues with lockout kits, seek assistance from qualified professionals or manufacturers for guidance and support.

Conclusion:

Lockout kit maintenance is essential for ensuring the effectiveness of safety measures in industrial environments. By following the tips outlined above, businesses can keep their lockout kits in top shape, enhancing workplace safety, minimizing the risk of accidents, and maintaining compliance with regulatory standards. Remember, proactive maintenance is key to safeguarding workers and promoting a culture of safety in the workplace.

The Ultimate Guide to Lockout Kits: Choosing, Implementing, and Enhancing Safety Measures

Lockout kits, also known as LOTO kits, are an essential component of workplace safety. These kits provide workers with the necessary tools and equipment to isolate machinery or equipment from its energy source during maintenance or repair work. Failure to implement proper lockout procedures can result in serious injuries or even fatal accidents. In this ultimate guide, we’ll explore the different types of lockout kits available on the market today and discuss what you need to look for when choosing one for your business. We’ll also cover how to implement a lockout kit effectively and enhance overall safety measures in your workplace. So let’s dive in!

What Is A Lockout Kit?

A lockout kit, also known as a LOTO kit, is a collection of tools and equipment designed to help workers isolate machinery or equipment from its energy source. Lockout kits typically consist of padlocks, hasps, tags, circuit breakers, and other safety devices that prevent the accidental release of hazardous energy.

When using a lockout kit, workers are required to follow specific procedures before performing maintenance or repair work on the equipment. These procedures involve isolating the energy source and ensuring that it cannot be re-energized until work is completed.

Lockout kits can come in various sizes and configurations depending on the type of machinery or equipment being serviced. Some kits may include specialized devices such as valve lockouts or electrical disconnects for specific applications.

Implementing proper lockout/tag-out procedures with a lockout kit helps ensure worker safety by preventing accidents caused by unexpected energization during servicing activities.

The Different Types Of Lockout Kits

Lockout kits come in various forms to cater to different industries and applications. The types of lockout kits that are available include electrical, mechanical, pneumatic, hydraulic, and combination lockout kits.

Electrical lockout kits are designed to prevent the accidental or unauthorized operation of electrical equipment during maintenance or repair work.

Mechanical lockout kits contain devices such as lockout padlocks and loto hasps which can be used to secure machinery with moving parts.

Pneumatic lockout kits prevent compressed air from being released accidentally during servicing procedures on pneumatically operated machines.

Hydraulic lockout kits similarly protect against any hydraulic energy that could potentially harm workers when working on hydraulic-powered systems.

Combination lockout kits may include a mix of devices from each category depending on the specific needs of a workplace.

When choosing a type of kit, it is important to ensure that it meets all relevant safety standards for your industry and application.

Pros and Cons Of a Lockout Kit

A lockout kit is an essential tool for any workplace that uses heavy machinery or equipment. It enables workers to safely shut down and isolate the energy source of a machine, ensuring that no one can accidentally start it up again while repairs are being made.

One of the major advantages of a lockout kit is increased safety. By making sure machinery cannot be turned on during maintenance or repairs, employees are protected from potentially dangerous accidents. Another benefit is compliance with OSHA regulations; using a lockout kit demonstrates a commitment to worker safety, which can prevent costly fines and lawsuits.

However, there are some downsides to using a lockout kit. One potential issue is decreased productivity, as shutting down machinery takes time away from production. Additionally, if not used correctly or consistently by all employees, a lockout system could lead to confusion and mistakes.

The benefits of implementing a reliable lockout system far outweigh any potential drawbacks. With proper training and usage guidelines in place, businesses can ensure their workers’ safety while maintaining efficient operations.

What to Look for When Choosing a Lockout Kit?

When it comes to choosing the right lockout kit for your workplace, there are several factors that you should consider. First and foremost, you must ensure that the kit meets all relevant safety standards and regulations.

Another important consideration is the size of your facility. If you have a large facility with many different types of machinery and equipment, you may need a more comprehensive lockout kit that includes a wide range of devices and tools.

It’s also important to choose a lockout kit that is easy to use and understand. Look for kits with clear instructions and diagrams so that employees can quickly learn how to properly secure equipment during maintenance or repair work.

Durability is also crucial when selecting a lockout kit. Your chosen kit should be able to withstand frequent use in harsh industrial environments without breaking down or losing effectiveness over time.

Consider purchasing from reputable manufacturers who offer good quality customer service, warranties, and technical support. This ensures that any issues or questions will be addressed promptly if they arise in the future.

Implementing a Lockout Kit

Implementing a lockout kit is an essential step in ensuring the safety of workers who operate machinery and equipment. The process involves creating standard procedures to isolate energy sources before performing maintenance or repairs.

The first step in implementing a lockout kit is to identify all possible energy sources that could cause harm. This includes electrical, hydraulic, mechanical, pneumatic and chemical energy sources. Once identified, each energy source must be isolated using the appropriate locks and tags from the kit.

It’s crucial to train employees on how to use lockout kits correctly as part of their job responsibilities. This training should emphasize the importance of following procedures strictly for every machine they work with.

After implementing a lockout procedure, it’s essential to conduct regular audits and inspections to ensure employee and management compliance. These assessments help identify any gaps in implementation so that corrective measures can be taken before accidents occur.

Implementing a lockout kit requires careful identification of potential hazards followed by strict procedural guidelines for isolating those hazards through locking out all forms of hazardous energy sources.

This ensures worker safety when maintaining or repairing machines while also reducing risks associated with such equipment operations.

Enhancing Safety Measures with a Lockout Kit

Lockout kits are a valuable tool for ensuring the safety of employees who work in settings where hazardous energy sources are present. However, simply having a lockout kit is not enough to guarantee workplace safety. It’s crucial to implement proper procedures and protocols to ensure that the kits are being used correctly.

One way to enhance safety measures with a lockout kit is by creating written procedures outlining how and when the equipment should be used. These procedures should include information on which machines or equipment require locking out, as well as specific steps for using the lockout kit properly.

Another important step in enhancing safety measures with a lockout kit is training employees on proper usage and maintenance of the equipment. This includes teaching them about different types of energy sources, identifying potential hazards, and demonstrating how to use each component of the kit.

It’s also essential to regularly inspect all lockout devices and replace any damaged or worn-out components promptly. Keeping an inventory of your company’s current supplies can help you stay ahead of future needs so that you’re never caught without necessary items.

It’s always wise to review your LOTO program periodically; this ensures that everything continues running smoothly while addressing changing conditions or needs within individual departments. With careful planning and attention-to-detail during implementation, businesses can successfully improve their overall level of workplace safety through comprehensive LOTO programs bolstered with reliable tools such as quality Lock Out/Tag Out (LOTO) Kits.

Conclusion

Lockout kits are an indispensable tool for keeping employees safe while working on potentially dangerous machinery or equipment. By using lockout kits, employers can effectively prevent accidents caused by unexpected start-ups and releases of stored energy.

When choosing a lockout kit, it’s important to consider the specific needs of your workplace and ensure that the kit includes all necessary components. Once implemented, it’s crucial to train employees on how to properly use the kit as part of their safety training.

Enhancing safety measures with a lockout kit doesn’t have to be complicated or expensive. By following best practices and regularly reviewing your procedures, you can create a safer work environment for everyone involved.

Investing in high-quality lockout kits is essential for any organization looking to prioritize employee safety. Taking the time to choose the right kit and properly implement its usage will go a long way towards preventing accidents in your workplace.

Checkout Our Popular Products:

- Osha lock

- Lockout station

- Scaffold Tag

- MCB Lockout

How Many Types of Group Lockout Box?

Loto Group Box physically locks the complete system such as the machine, equipment, and even process in the safe mode. Lockout and Tagout is the Control of Hazardous Energy which involves with isolation of energy from the system.

What is the Benefit of Group Lockout Boxes?

The Group Lockout Boxes are storage devices used to capture keys to make effective lockout of large equipment. Moreover, all the lockout is enabled with a single padlock to secure the equipment.

Lockout devices offer the best way to easily secure the machinery equipment. These have circuit breaker lockout along with the electrical plug lockout device.

The Use of Group Lockout Box keeps all the keys safely and is enabled with the safe key storage facility. All the lockout points on Loto Box are also easily accessible.

Types of Loto Group Lockout Box

These are storage devices that can be used to capture keys for effective lockout of equipment. These lockout tagout products are certified raw materials used, so they would enhance the functionality. The lockout point on equipment is secured with a single padlock.

Master Lock Group Lock Boxes S600 Series

Normally, the Master Lock Group Lock Boxes S600 Series have 430-grade stainless steel. These can easily withstand the harshest environments as they have a tough structure with superior design features.

It makes lock boxes stronger and easier to use. The Master Lock Group Lock Boxes S600 Series has a stackable design suitable for storage. It also helps with making quick transporting of multiple boxes.

Portable Red Group Lockout Box

The Master Lock Portable Red Group Lockout Boxes are suitable for capturing the keys from lockout points. It is easier to secure a lockout point even with a single piece of equipment.

Group Boxes and Loto Kits Capture keys from lockout points and easily place them in the lockbox. The Lockout Boxes are suitable for the padlock or other fixed devices.

However, it offers flexibility for the lock. This easy-to-grip is perfect for wide areas like machinery, the safety of workers, and other equipment. Read More: Advantages & Disadvantages of Lockout Tagout

Lockout Safety Heavy Duty Lockout Box

The Lockout Safety Heavy Duty Safety Lockout Boxes provide durability as well as flexibility, ensuring better access for all parties.

Furthermore, safety Lockout Boxes are also perfect for group lockout situations. All the keys have identification tags with multiple boxes under control.

Lockout Safety Portable Red Group Box

The Group Lockout Box model ensures the machine or keys in the machine are fully secure. Moreover, it accommodates up to 7 safety locks with easy to carry around. Group Lockout Box offers the best way to lock all the parts in the machine.

You May Also Like: What is an Electrical Panel Lockout Box and Its Uses?

You May Also Like: What is the Purpose of Lockout Tagout: Advantages & Disadvantages

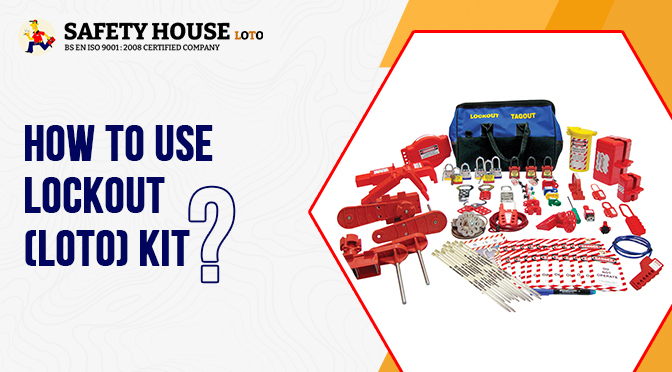

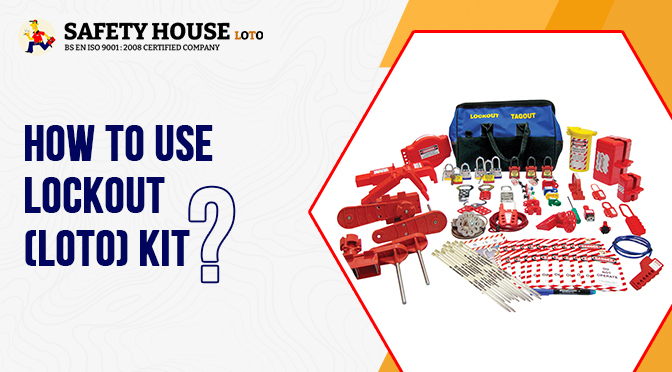

How To Use Lockout (Loto) Kit?

The lockout kit is the bunch of gear accessed for performing lockout techniques on the hazardous hardware. The use of lockout kit becomes unavoidable in the industrial area where safety should be observed. Loto means lockout tagout, which is the necessary safety procedure for protecting employees and workers around the equipment and machinery they operate, maintain, and service.

It is also a vital OSHA-inspection focus and remains one of the most cited violations for the general industry. Moreover, lockout Tagout is the procedure used to ensure that equipment/machinery is shut down and inoperable until the completion of repair or maintenance work.

A company should educate their employees on how to use loto kit properly to keep themselves safe from machinery that could injure or kill them when not managed correctly. Continue reading to know the major Loto Kit uses and how to use the kit properly to ensure workers’ safety!

Things to know about lockout kit

The lockout kit is accessed on electrical gear, hardware, and plumbing frameworks to minimize the likelihood of wounds from unforeseen happenings. Furthermore, this kit accompanies several types of locks and recognizable proof tags. The use of lockout kit renders workers a strategy for referring to data about the perils relevant to the locked-out hardware.

Moreover, the loto kit uses are extensive because it has lots of safety tools and equipment such as lockout padlocks and valve lockout devices. It is extremely useful for different situations. Manufacturers provide basic to advanced lockout kits, but you must buy the right kit suitable for your work environment.

But, remember that the major use of lockout kit is to protect the workers of the industry when accessing dangerous and harmful machines. In addition, this kit minimizes the inadvertent activity of machines under maintenance.

How to use the lockout kit?

Are you thinking about how to use lockout tagout kit? If yes, you should become aware of the tools and equipment available in the kit. Knowing the usage of every tool in the kit is important to enjoy its benefits completely.

- The lockout tagout box kit also contains the equipment that needs to be worn to minimize hazards and other safety tools accessed on the machinery.

- The loto process lets energy be removed from the situation and prevents all unintended motion and energy discharge.

- Keep in mind that locking and tagging out the machine does not prevent hazards completely.

- Follow the employer’s safety guidelines and caution all the time. Knowing how to use lockout kit properly will help employees sort out complicated situations without any damage.

If you want to access the best Loto kit, Key Box, and other safety house products, you should engage with a reliable Loto kit manufacturer like us. The professional will explain the loto kit uses and the procedure to utilize it properly.

Top Danger Lockout Tags and Caution Labels

Many companies place a high value on maintaining a flawless locking mechanism to safeguard their employees and outsiders. These safety Danger Lockout Tags alert people to potential dangers if a machine or piece of equipment is turned on.

For businesses to identify the energy source and who is using the machine or equipment, lockout tags must be used. It serves as both a visible reminder and a physical barrier for safety reasons.

As an example of an application related to energy release, the tag may be used in conjunction with switches such as Blocks Disconnect. The Lockout Tagout Products rely heavily on tags. Lockout tags of lockout India safety house provide information about the lockout state and may identify the individual repairing it.

- The ability to withstand the conditions in which they are used

- Standardization and differentiation from other tags are key requirements for labels.

- Include specific cautions and directions.

- Securely fastened using a 50 lb pull-force-resistant, non-reusable self-locking mechanism

Top Best Danger Lockout Tags List

Lockout tags are widely available nowadays to safeguard the machine and its components; here are the top danger lockout tags. Consider many kinds of safety lockout devices and choose the most appropriate one for your business to optimize security.

Danger Caution tag

Caution tags are used when there is a low risk of death or serious injury, but there is a possible danger that may not be immediately apparent.

Do to operate tag is used by companies to ensure the safety of their workers and staff. Moreover, personnel should be informed and warned before operating the machinery or equipment to prevent accidents.

Lockout tag for machinery

This huge risk may avoid with an efficient lockout procedure. Furthermore, using the equipment lockout tag of Loto Kit is the best way to keep yourself safe while keeping the isolated energy device in the appropriate place.

The fire inspection tag

Using a fire inspection tag is the easiest way to keep track of the extinguisher’s current state. In a fire, having well-maintained extinguishers on hand is essential. Furthermore, sometimes, fire inspection tags are also used on Valve Lockout to ensure the safety of the worker.

Photo tag with a lockout

Industries use the lockout picture tag to add a photo to their lockout and safety programs. Moreover, this danger lockout tag comes with a transparent pocket where you can put your employee’s picture or ID to give safety and accident prevention a personal touch.

Scaffold tag

Employees who work on scaffolds rely on Scaffold Tags to keep themselves and their colleagues safe with the best danger lockout tags. Such things are used by businesses to protect the health and safety of their personnel. In addition, it keeps track of a variety of specifics, such as restrictions, limitations, and safety data related to a certain scaffold.

Conclusion

Business owners and peoples use the finest expertise to pick up lockout tags for industrial safety and ensure total protection. Our Safety House Loto is the best Lockout Supplier company that helps to maintain safety for your business.

You Might Also Like: Types of Lockout Tags & Its Usage for Industrial Safety

You Might Also Like: What is a Lockout Kit And Why is it Used For?

You Might Also Like: Safety House Loto Products For Safe Work Environment

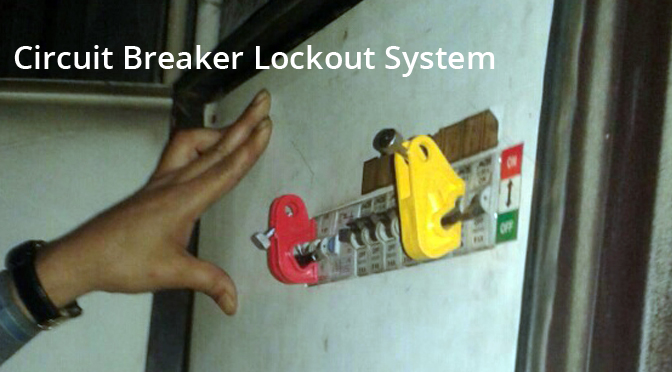

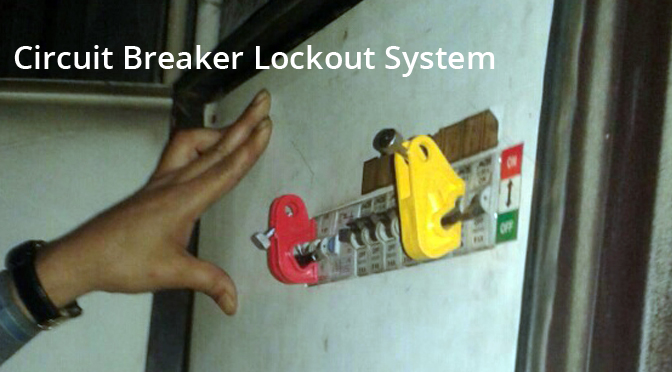

Circuit Breaker Lockout System

You must have observed MCB’s (Miniature Circuit Breaker) installed in your house. When you switch on or shut-down the appliance, the electricity of an entire floor gets affected. This is because all the circuits in the floor are connected with the MCB Lockout and by turning off the main switch, the lights go out. However, this is not the prime task of a circuit breaker but to protect the appliance and the people from potential electrical shocks and faults. In other words, Circuit Breakers are the appliances that blocks possible electrical short-circuits and helps maintain the flow of electricity.

A lot of people fail to comprehend the reason as to how Circuit Breakers come under the OSHA guidelines. As per OSHA’s standard 29 CFR 1910.147, all the devices that are dangerous and can cause accidents must be disconnected from all kinds of appliances, including Circuit Breakers so that the machines can’t operate itself in absence of workers. And since Circuit Breakers are basically like a switch with on/off system, it’s required to count them in Lockout-Tagout procedure.

Circuit breakers lockout system involves locking out the switches of the circuits through circuit breaker lockout equipment. The kit includes yellow rail assembly, 2 x 1-way pins, 1 x 2-way pins, 1 x cup pin, pin holder, and self tapping screws which come specifically designed for each panel. The process of killing the switches is very easy through the Lockout Kit.

There are numerous lockout-tagout service providers in the country. However, not all of them deliver quality products to their customers. ‘Safety House’ is a trusted company that has been in business since a considerable amount of time and has hundreds of satisfied clients. So make sure to choose the best LOTO service provider for your establishment which meets your requirements.

Checkout Our Other Lockout Tagout Products:

- Lockout hasp

- Group Lockout Box

- Lockout Station

- Valve Lockout

Enquire Now

Five Most Cited Serious Violations As Per OSHA – II

Scaffolding: OSHA asks every scaffold and scaffold component to be able to support without any failure not just its own weight, but at least four times the maximum load intended to apply to it. There are of course exceptions to this rule, such as suspension ropes, used on suspension scaffolds that are non-adjustable. These should be capable of supporting at least six times the maximum weight intended to be transmitted to it.

Respiratory Protection: OSHA asks for preventing atmospheric contamination, so that occupational respiratory diseases are not caused by inhaling any harmful vapor, spray, smoke, gas, mist, fume, fog and dust. This is to be achieved by using materials that are less topic, conducting operations in an enclosed area, ventilation and other engineering control measures. If such measures are not feasible, respirators are to be provided to the workers.

Lockout Tagout: Appropriate LOTO devices must be used to prevent unexpected energization/ release of stored energy from machines.Equipment must be tested to verify the effectiveness of lockout tagout products and other energy control measures. The employer is to provide training so that the function of the energy control program is understood by the workers. This section covers the servicing of machines and equipment.

As the top manufacturer of LOTO devices, Safety House provides products like lockout tagout kit and key cabinet at reasonable prices.

To Continue Click Here

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Five Most Cited Serious Violations As Per OSHA – I

Readers of the blog of New Delhi, India-based manufacturer of Lockout products, ‘Safety House’ would know that our wide range of products is as per OSHA. In the last bog post, we gave you an insight into top violations as cited by the federal agency of the United States Department of Labor. Today, we discuss five serious violations in detail. (For those unaware, OSHA releases a list of top serious violations every year.)

Fall Protection: Employers must provide fall protection systems. Like all other points, this is vast, but employees need to determine if walking surfaces have the strength to support employees. Walking surfaces that are over 6 feet above a lower level must be protected through guardrail/ safety net/ personal fall arrest systems. Same goes for every worker constructing a leading edge 6 feet or more above a lower level. The only exception to this rule is when an employer can ‘demonstrate’ that using these systems, on the contrary, poses greater harm. The employer in this case would be required to develop an alternate fall protection system.

Hazard Communication: This is concerned with chemical safety at workplaces. Of prime importance is the fact that hazards by chemicals must be identified, and available to/ understood by workers. Signs and right-to-know placards should be used. The requirements of the hazard communication section by OSHA are consistent with UN’s GHS, i.e. Globally Harmonized System of Classification and Labelling of Chemicals. lockout supplier

To Continue Click Here

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Lockout Tagout And OSHA

Posted On: February 3, 2016

Categorized In: Lockout/Tagout

Written By: Lockout India

At Safety House (LOTO), we adhere to OSHA (Occupational Safety and Health Administration) guidelines while manufacturing lockout tagout/ workplace area safety/ site management products. Our range of products includes key cabinet, This blogpost would give you an insight into what OSHA is, and why following it is imperative for the safety of your employees. lockout supplier

The main federal agency of the US Department of Labor, OSHA was established in 1971 by the Congress under the Occupational Safety and Health Act. The mission of the agency is to “assure safe and healthful working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education and assistance”.

OSHA’s health and safety standards are aimed at preventing accidents and accidental use of energy. The federal agency enforces the development, documentation, implementation, and enforcement of energy control procedures. It recommends that only lockout/ tagout devices authorized for a particular machinery or equipment are used, and that these devices are durable, standardized and substantial. It also asks to ensure that lockout tagout devices identify individual users. OSHA further recommends the establishment of a policy that permits only the employee who applied a LOTO device to remove it. Energy control procedures need to be inspected at least annually. Furthermore, effective training is to be provided for all employees.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Lockout Procedures to Follow

Posted On: January 19, 2016

Categorized In: Lockout/Tagout

Written By: Lockout India

Lockout means shutting out machines. An industrial machine shuts for maintenance and servicing activities. It is carried out as a safety measure. The maintenance workers might injure themselves by their sudden startup. There is a certain lockout procedure implemented during the whole process. This process is undertaken by following every known guideline as given by OSHA.

As Lockout India creates safety equipment for such processes, we believe that you, our beloved readers should have an idea of the procedures followed during the process. Please note that the steps we are about to mention are general guidelines or sample steps. In reality, something very close to them is followed because admit it, “field work is much different”.

We need to understand 3 main criteria’s while learning the procedure.

- System – refers to the machines/equipment

- Authorized Employee – refers to the expert who carries out the full procedure

- Affected Employee – includes the workers, various staff members etc. who aren’t qualified to carry out the process

Lockout Procedures

Shutdown

1. The first step is to turn off all the energy sources from the operator’s panel. However, the authorized employee has to make sure that none of the affected employees are still operating as sudden power loss could lead to major accidents.

2. After power shut, notifying the affected employees is the next step. They are to leave their stations immediately and await further instructions.

3. The third step now is to shut down the whole system using normal stopping procedures like powering down, stoppers etc.

Lockout/Tag out

1. Firstly, isolate the system from any energy source. This process is called energy isolation.

2. Lockout and Tag out the system with appropriate safety products.

3. Release any stored energy from the springs, capacitors, hydraulics etc. This is very important as the residual energy in these parts could release automatically during maintenance and harm the crew.

4. Confirm that isolation has actually taken place by trying the equipment.

5. If system doesn’t start means it’s in lockdown mode.

Maintenance

Let the crew carry out maintenance and servicing.

In the meantime, continue your verifications through inspections, observations and tests.

Restarting the System

- After maintenance, remove all the locks and tags.

- Clear out all personnel and unnecessary items from the area.

- The main system shall be then restarted.

- Check whether all machines are working as they should.

- Finally, notify all the employees to resume their work.

One main thing to be kept in mind is that sometimes the work scale is too big meaning multiple authorized employees are involved. However, the procedure is more-or-less ‘the same’. It is unfortunate to say that despite several listed Lockout Tag out procedures, every year thousands of work infringements take place due to non-compliance of appropriate protocols. We, thereby urge all those who are reading this and work in the industry to go through the guidelines provided by OSHA in detail. In case you need further help regarding Lockout Tag out and safety-insured products, ping us!

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now