Elements Of OSHA’s Lockout-Tagout Standard

The elements of Osha Lockout Tagout Standard (29 CFR 1910.147) is a 4-page general industry standard, which was first published in 1989. It was formulated with the single aim of preventing accidental startups of machineries and equipments during their maintenance or service. It lays importance on isolating hazardous energy sources and rendering them isolated. The energy sources include hydraulic, thermal, electrical (stored and active current), chemical, gravitational force, pneumatic and mechanical.

A lockout/tagout program includes 3 basic elements:

1. Written Procedures: These written procedures communicate important information workers involved in lockout/tagout procedures and identify what needs to be done and when. They also prescribe the processes of shutdown, isolation and applying and removing lockout/tagout. Such procedures are only needed for machineries with 2 or more energy sources.

The following should be clearly specified:

– Specific machineries and their shutdown/isolation processes

– Where the lockout devices are installed

– How to de-energize stored energy

– How isolation needs to be verified

2. Training Programs: Training is mandatory for two types of employees, namely authorized employees and affected employees, where the former the people who maintain and service machineries and are qualified enough to control hazardous energies, and the latter are those work in close proximity to the machines/equipments being serviced or repaired under lockout/tagout and need to understand the hazards involved.

3. Timely Audits: Periodic audits ensure that the energy control procedures continue to be correctly implemented, the workforce do not deviate from the procedures and are familiar with their responsibilities. It must take place at least annually. These are also helpful in correcting procedural inadequacies.

Basic steps to lockout/tagout program:

1. Preparation – Think and Plan: Think through the entire procedure. Identify the energy sources that must be controlled and the methods which would be used.

2. Communicate and Notify: The authorized personnel needs to communicate the following to the affected employees:

– The machine that would be locked out and why

– How long will the process take

– Name of the employee responsible for lockout

– Who needs to be contacted for further information

3. Neutralizing the Equipments: It involves disconnecting the electricity, blocking the movable parts, releasing the spring energy, draining or bleeding hydraulic/pneumatic lines and lowering the suspended parts to rest positions.

4. Locking Out: Use lockout devices specific to the machinery. There should be as many locks as the people involved in the process and each person should have a personal lock and key placed on the machinery. Further, it should be noted that locks can only be unlocked by those who installed them.

5. Tagging Out: Tag the machineries, controls, and suspended parts. Tags should also include the contact details of and reasons for locking out.

Verify: Before you continue further, verify if the setup is completely locked out or not.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Importance of OSHA’s Lockout/ Tagout Standards

OSHA (Occupational Safety and Health Administration) is a U. S. Government office entrusted with shielding and directing exercises in the working environment. As a major aspect of the U. S. Work Department, they are in charge of implementing well being and well being benchmarks in each area of business and industry. The directions they have instituted particular to ‘Lockout/Tagout’ are intended to ensure faculty dealing with stimulated hardware for the reasons for set up, adjusting and upkeep.OSHA Lockout Tagout Standards

There are particular enterprises that either are essentially not secured nor have their own particular principles on lockout/tagout for the purpose of warehouse safety:

• While there are other OSHA principles that apply for electrical stun and consume danger, the general standard does not matter to electrical risks from work on, close, or with transmitters or gear in electric use (start wiring) establishments, which are laid out by Subpart S of 29 CFR Part 1910.

• Controlling risky vitality in establishments for the selective reason for power era, transmission, and appropriation, including related gear for correspondence or metering (these sorts of establishments are secured by 29 CFR1910.269).

• Agriculture, development, and oceanic enterprises or oil and gas well boring and overhauling are not secured by the OSHA general standard on lockout/tagout.

The safety programs require significant investment a composed program, including gear particular methods must be established and representatives must be prepared and cash an adequate number of vitality detaching gadgets, (for example, locks) must be acquired and kept up and is regularly observed as badly designed. Therefore, a few managers will attempt to fit a circumstance into an exemption trying to work around the LOTO products and devices for direction since they would prefer not to manage the time, exertion, and burden. In any case, these programs anticipate the occurrence of chances frequently bringing about funds in specialists’ pay costs much more than that of the lockout/tagout program-and spares lives. On the off chance that a machine or bit of gear really does not should be stimulated amid adjusting or support, it ought to be bolted out.

A bolt out gadget is intended to physically cripple a bit of gear absolutely, in this manner keeping its inadvertent operation. These can be as switches on an electrical board or chains and bolts on a valve. Pins, key-squares and wedges are altogether utilized as a part of various applications. Just particular locking systems ought to be utilized on particular bits of gear. Where physical lockout is impractical, a tagout framework will give visual cautioning with regards to the threat display. They will regularly clarify the reason a specific machine is out of administration and demonstrate the person(s) in charge of playing out the important upkeep. Labels are just used to give data and are not a suitable substitute for a locking instrument, if locking is conceivable.

Inability to initiate and take after a compelling Lockout/Tagout program can open laborers to genuine damage and even demise. Numerous wounds have been avoided by appropriately taking after these vital rules. The vast majority of it is judgment skills. Like the directions going with any electrical apparatus in your home, the best exhortation is to “separate from the power before adjusting”.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Why Lockout And Tagout Are Essential For Safe Car Wash

Time and again we have talked about the importance of Tagout and Lockout safety procedures and why they are such essential requirement of every workplace. These devices are used by big and small businesses to ensure that they offer a very safe working environment to their workers. The safety of employees should be of utmost importance to the employers and in order to avoid any mishap or accident from happening they need to deploy Lockout Tagout Products. Lockout And Tagout For Car Wash

LOTO Kit ensure that there is no unrestrained discharge of energy and accidental start up of equipment and machinery. While Lockout devices prevent equipments from accidentally starting up or switching off, Tag-outs are energy isolation devices that are placed in the safe position with a written warning attached to it.

These safety measures apply to car was places as well, while handling car wash equipments effective lockout/Tagout (LOTO) become necessary. They are important as they can easily prevent any serious injury in case of an accident and also they are in accordance to Occupational Safety and Health Administration (OSHA). The increasing occurrences of accidental startup of devices and the overall dangers that they pose to workers is a serious concern and OSHA has carefully created guidelines in order to ensure workplace safety. Car wash places also come under those guidelines and that makes it compulsory for employers to apply lock or tag on equipments in the off or safe position. The goal of such program is to make sure that no worker ever loses their lives or limbs to any fatal accidents that could be easily prevented; of course it is equally essential to make sure that the employees are well acquainted with the guidelines and procedures too.

Safety House LOTO is a leading manufacturer of high quality Lockout Tagout Products. All our devices meet the OSHA standard and are the preferred LOTO equipments by many corporate giants. manufacturer of lockout products

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Lockout-Tagout Strategy Missing From Amputation Case

We all know the worth of OSHA’s Lockout-Tagout system. We have discussed about the Lockout Tagout Strategy from top to bottom in our previous blogs. However, going by the accidents that are happening around the globe, I guess it is the time to reconsider the viability of the procedure for the reason the same events that used to happen earlier are still taking place.

By accidents we are referring here to the death of workers through any sort of carelessness in operating detrimental machinery. OSHA’s facility in USA have reported that a beverage company namely ‘Kerry incorporated’ was violating the lockout-tagout procedure. Counting the company works on large scale as it has its branches in six continents and gives employment to approximately twenty-thousand workers, putting everyone’s life in danger is nowhere a responsible move.

The enterprise came into the picture when last week on December 5, the company broke some serious laws. Not only that but also processed them repeatedly. It was delineated that a worker’s forearm got stuck in a machine which further lead to multiple fractures. The injury happened mere six weeks late when another employee met with an accident at the same facility.

In both of the incidents it was observed by the federal safety inspectors that the enterprise wasn’t following the rules and regulations prescribed by OSHA for Lockout Tagout Products. The bigger injury that happened to a fifty plus year old guy whose arm was harmed while he was performing routine maintenance raises a serious question that why the industry owners does not comply with OSHA’s LOTO process?

We fully know and understand that Lockout Tagout Procedure is the best way to prevent any possible catastrophe from ever happening in an industry. Since many injuries which are repeated in almost every company can be avoided through the procedure, it is strictly foolish to not instigate Lockout-Tagout procedure in your firm.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Tagout Products

Enquire Now

Best Ways To Avoid Conflict With OSHA

It is said that smart people are those who learn from their own mistakes. But smartest are the ones who learn from the mistakes committed by others. Today we bring you a very interesting blog regarding how you can avoid getting in trouble with OSHA (Occupational Safety and Health Administration). manufacturer of lockout products

It has happened numerous times when industrial men won’t listen to OSHA and completely ignore their prescribed guidelines of implementing Lockout Tagout system in order to secure the workplace and the life of the staff employed. This often leads to conflicts with the supervising establishment and it is advisable to never disrespect your bread and butter. Reason being OSHA has the right to shut down a firm or extricate the employed staff from the organizations where the guidelines aren’t followed.

So, if you want to steer clear of facing any kind of trouble with OSHA and wish to eschew any catastrophic accident happening in your organization, keep note of the following things: –

Ensure your Lockout-Tagout practices are appropriate to the way they are prescribed in OSHA’s guidelines to safeguard the employees against possible injuries such as amputations, or even death. Always ask OSHA for any query if you may have any.

Always report about damaged or missing guards and never ever bypass a moving device. Until and unless the damaged machinery is repaired or replaced, make sure all of your workers are taking necessary precautions.

Update yourself with all the MSDS information of the chemicals that are used by you and your employees on site. Ensure you are providing protective workshops and training to the staff.

Considering most of the injuries happen due to lack of safety operating procedures, deficient safety-rule and inadequate training given to employees, always make sure your establishment never falls into any of these three categories.

Learn to use cords flexibly. Practice running extension cords overhead or taping them down to avoid tripping.

It is hard to keep track of all the safety guidelines prescribed by OSHA so at least by adhering to the above mentioned techniques, you can hope for a secure workplace and obviously manage to keep OSHA away from raining down on you. For more relevant information regarding Lockout-Tagout procedure, stays tuned to our blog and if interested in purchasing LOTO Kit, feel free to order online because we are the best Lockout-Tagout product manufacturer in India.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Why Are Cylinder Lockouts Important?

Amidst frequent news of workers losing their limbs or their lives due to the accidental startup of machinery or equipment, it has become even more essential to put a padlock on energy control devices. OSHA has laid down strict guidelines to assure that no one faces hazardous consequences of accidental energization of machinery. It is absolutely necessary to make use of lockout and tagout devices to make sure your workers are guarded against any such work place accident and have a safe and favorable environment to work in. Cylinder Lockouts

One such important lockout device is the Cylinder Valve Lockout that is used to prevent accidental ignition of gas cylinder. Gas cylinders are very common these days but they contain within a very highly inflammable energy that can be fatal if its overlooked. It is absolutely important to safely secure that highly inflammable energy and to make sure that no unauthorized person can get access to the cylinder. Cylinder Valve Lockout devices are made with the intent to prevent access to the main valve handle on many cylinder tanks.

In the absence of a lockout/ tagout device there is a high chance of the machine unexpectedly starting up. The lockout device isolates the hazardous energy source and renders them inoperative until work can begin again. It is important to identify all appropriate energy sources and implement lockout and tagout on them, these machinery or equipment must only be handled by authorized employees who are in charge of servicing or maintenance work.

Safety house LOTO who is ISO certified and the leading manufacturer of high quality lockout and tagout products, designed as per OSHA standards has its own range of cylinder lockout which is made with Polypropylene and weighs 115gms. The size of the cylinder lockout is 3.45″ x 6.15″ and it has 2 or 3 upper plate attached with rivets.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Cylinder Lockouts

Enquire Now

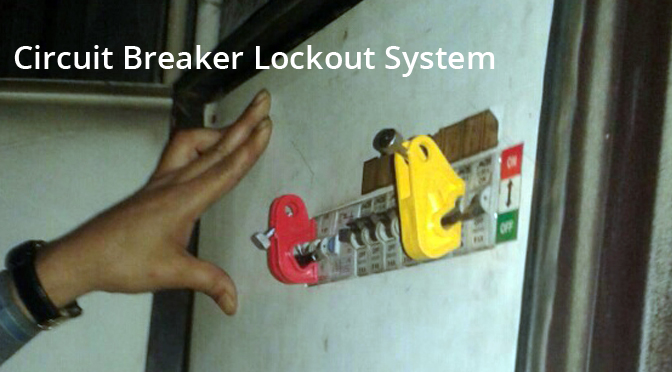

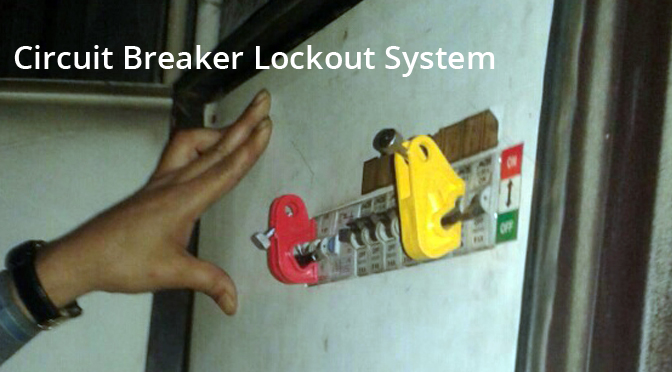

Circuit Breaker Lockout System

You must have observed MCB’s (Miniature Circuit Breaker) installed in your house. When you switch on or shut-down the appliance, the electricity of an entire floor gets affected. This is because all the circuits in the floor are connected with the MCB Lockout and by turning off the main switch, the lights go out. However, this is not the prime task of a circuit breaker but to protect the appliance and the people from potential electrical shocks and faults. In other words, Circuit Breakers are the appliances that blocks possible electrical short-circuits and helps maintain the flow of electricity.

A lot of people fail to comprehend the reason as to how Circuit Breakers come under the OSHA guidelines. As per OSHA’s standard 29 CFR 1910.147, all the devices that are dangerous and can cause accidents must be disconnected from all kinds of appliances, including Circuit Breakers so that the machines can’t operate itself in absence of workers. And since Circuit Breakers are basically like a switch with on/off system, it’s required to count them in Lockout-Tagout procedure.

Circuit breakers lockout system involves locking out the switches of the circuits through circuit breaker lockout equipment. The kit includes yellow rail assembly, 2 x 1-way pins, 1 x 2-way pins, 1 x cup pin, pin holder, and self tapping screws which come specifically designed for each panel. The process of killing the switches is very easy through the Lockout Kit.

There are numerous lockout-tagout service providers in the country. However, not all of them deliver quality products to their customers. ‘Safety House’ is a trusted company that has been in business since a considerable amount of time and has hundreds of satisfied clients. So make sure to choose the best LOTO service provider for your establishment which meets your requirements.

Checkout Our Other Lockout Tagout Products:

- Lockout hasp

- Group Lockout Box

- Lockout Station

- Valve Lockout

Enquire Now

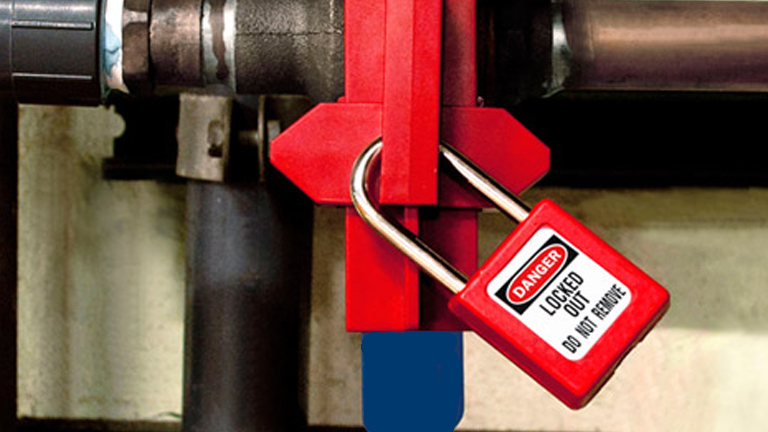

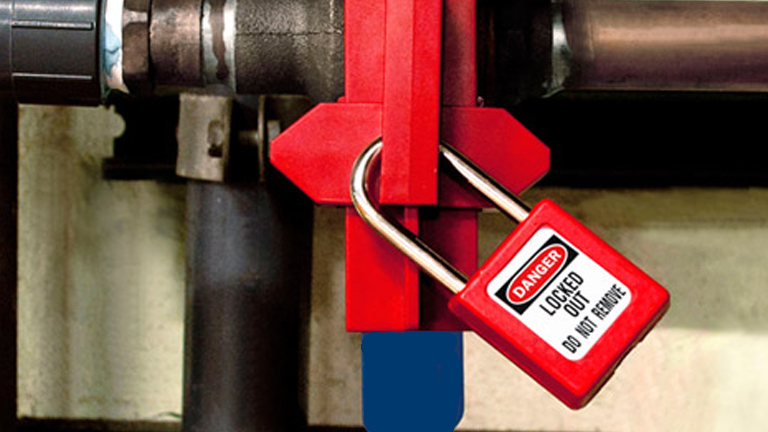

Why Valve Lockout Devices Are A Necessary Workplace Requirement

The safety and security of the workforce is important for any organization and it is their duty to ensure that the employees work in a hazard fee environment. The unexpected energization or startup of machines can pose some serious threat to the workers. Lockout Tagout Products provides protection that hold energy isolation devices in a safe position and prevents the release of hazardous energy and prevents machines or equipments from getting energized. In case machinery that the company employee is servicing or maintaining unexpectedly energizes, starts up, or releases stored energy then it can have very fatal consequences and injure the worker concerned.

Valve Lockout Devices For Workplace

Similarly valve lockouts prevent the occurrence of any harmful accidents during maintenance or repairs. With the help of Valve lockout devices workers can close off or isolate energy sources such as electricity and hydraulic pressure. By the statistical data compiled by OSHA (Occupational Safety and Health Administration) three million workers that majorly include electricians, machine operators, and laborers face this risk at work places. A victim can fracture their arms or legs, get burnt or electrocuted in the light of such an accident occurring. This is a serious issue on a personal level as the life and physical health of a laborer is concerned and also staff getting injured would gravely affect the productivity of an establishment.

Valve Lockout device is easy to use, safe and an inexpensive way to secure valves and prevent injury. They are used at workplaces to close off different kinds of pressured valves, these devices ensure that machineries that are value operated do not accidentally start working and remain switched during any maintenance work. The Valve Lockout Devices are attached over the operational part of the valve.

Safety House, the best manufacturer of lockout products In Delhi emphasis on taking prevention measures rather than waiting for accidents to happen. We also manufacture a wide range of the best Valve lock out Device.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Loto Kit

Enquire Now

Checklist For Better Use of Lockout/Tagout Program

Lockout/ Tagout acceptance in your workplace is an essential safety requirement. Preventing the unpredictable accidents of dangerous gasses or energies during service and maintenance ensures the safety of workers and helps to build a productive work environment. Lockout Tagout Products require proper adoption and implementation for workplace and employees. According to a report of Occupational Safety and Health Administration (OSHA), around three million people working with big equipment or machines face the risk of injuries if lockout/ tagout (LOTO) is not properly implemented. This blog post will provide few tips to help your company stay disciplined.

Choose The Right Device: The lockout padlock is one of the important parts of LOTO family. Valves, circuit breakers, switches, etc. are just some of the machines that require lockouts. Sometimes purchasing the right type of lockout may seem overwhelming as these products come in many variants.

Before buying a padlock for your workplace, few things are going to help you a lot:

1. Knowing the exactly right product and use devices verified as per OSHA standard.

2. Make a list of machines that may need lockout devices.

3. Always use standardized goods and tools to keep devices organized.

Lockout Station is an effective way to hold critical devices. This product not only stores important devices, but also they save space, time and efficient operations.

Complete Document Strategy: Lockout implementation needs to be documented by process. This process will help to remove any possible confusion about the ability of management and workers. Documentation also provides employees with valuable training tips. Fixed documentation provided by OSHA is required, given the differences in workplaces and machines, not every Lockout procedure will be the same. It Is very important to make sure the systems are as efficient as possible.

Establish An Attentive Training Program: Careful and thorough training is an essential part of a successful lockout program. All workplaces need to be trained according to their need. It is imperative for each and every worker to his role. Work should be explicitly assigned and defined to the appropriate employee. Strong communication is required to develop among all employees so that they clearly alert affected employees when a lockout device is being placed and removed. Every padlock has a space to write worker’s name.

Careful Evaluation: A careful evolution is a crucial for development. Lockout training and written procedures can be counted as a success, only if they are used in actual maintenance situations. Analysis is important to make sure that the training exercises, procedure, and devices are working properly.

Take a look at LOTO products at www.lockoutindia.com and decide if the products shown on the website will meet all your criteria necessary protect employees while working.

Checkout Our Other Lockout Tagout Products:

- Lockout Hasp

- Group Lockout Box

- Lockout Padlocks

- Valve Lockout

Enquire Now