Importance of OSHA’s Lockout/ Tagout Standards

OSHA (Occupational Safety and Health Administration) is a U. S. Government office entrusted with shielding and directing exercises in the working environment. As a major aspect of the U. S. Work Department, they are in charge of implementing well being and well being benchmarks in each area of business and industry. The directions they have instituted particular to ‘Lockout/Tagout’ are intended to ensure faculty dealing with stimulated hardware for the reasons for set up, adjusting and upkeep.OSHA Lockout Tagout Standards

There are particular enterprises that either are essentially not secured nor have their own particular principles on lockout/tagout for the purpose of warehouse safety:

• While there are other OSHA principles that apply for electrical stun and consume danger, the general standard does not matter to electrical risks from work on, close, or with transmitters or gear in electric use (start wiring) establishments, which are laid out by Subpart S of 29 CFR Part 1910.

• Controlling risky vitality in establishments for the selective reason for power era, transmission, and appropriation, including related gear for correspondence or metering (these sorts of establishments are secured by 29 CFR1910.269).

• Agriculture, development, and oceanic enterprises or oil and gas well boring and overhauling are not secured by the OSHA general standard on lockout/tagout.

The safety programs require significant investment a composed program, including gear particular methods must be established and representatives must be prepared and cash an adequate number of vitality detaching gadgets, (for example, locks) must be acquired and kept up and is regularly observed as badly designed. Therefore, a few managers will attempt to fit a circumstance into an exemption trying to work around the LOTO products and devices for direction since they would prefer not to manage the time, exertion, and burden. In any case, these programs anticipate the occurrence of chances frequently bringing about funds in specialists’ pay costs much more than that of the lockout/tagout program-and spares lives. On the off chance that a machine or bit of gear really does not should be stimulated amid adjusting or support, it ought to be bolted out.

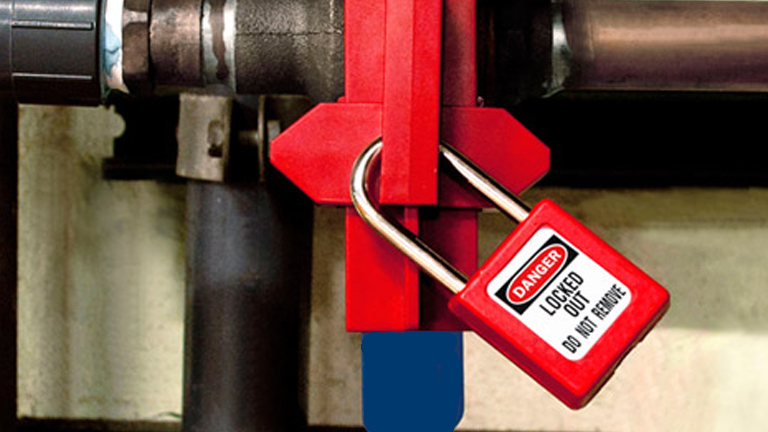

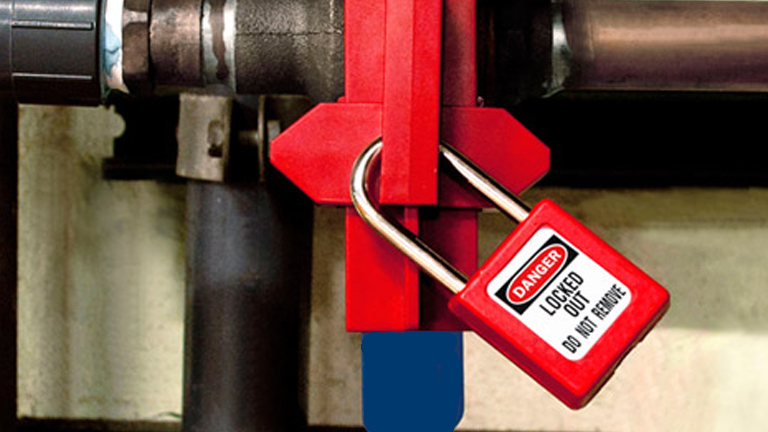

A bolt out gadget is intended to physically cripple a bit of gear absolutely, in this manner keeping its inadvertent operation. These can be as switches on an electrical board or chains and bolts on a valve. Pins, key-squares and wedges are altogether utilized as a part of various applications. Just particular locking systems ought to be utilized on particular bits of gear. Where physical lockout is impractical, a tagout framework will give visual cautioning with regards to the threat display. They will regularly clarify the reason a specific machine is out of administration and demonstrate the person(s) in charge of playing out the important upkeep. Labels are just used to give data and are not a suitable substitute for a locking instrument, if locking is conceivable.

Inability to initiate and take after a compelling Lockout/Tagout program can open laborers to genuine damage and even demise. Numerous wounds have been avoided by appropriately taking after these vital rules. The vast majority of it is judgment skills. Like the directions going with any electrical apparatus in your home, the best exhortation is to “separate from the power before adjusting”.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Never Ignore Workplace Safety

If we say that a belonging can come in a working environment that can only be achieved or attained by keeping the employee safe, if a employee is not safe or does not have safe working environment he/she will never be happy will not religiously work for you and may commit mistakes while working, the mistake can go up to that extent that a working operator can meet with a sever accident and can lead death. Workplace Safety

Definition of Safety

Safety as the word suggest means creating safe working environment like having sufficient amount of light while doing so critical work, optimum exhaust openings while doing some job which may include use of hazardous effluents, use of gloves while working on machines, use of helmet when working on height, wearing shoes when in workshops. Ergonomics is also considered as one of the most important part of occupational health and safety as a proper layout is made and the execution is laid accordingly helps in reducing the chances of workers fatigue. This applies not only to those working on computer workstations but also to those using equipment which are controlled from one place. The principles of ergonomics apply to all workers who spend hours sitting in the same position.

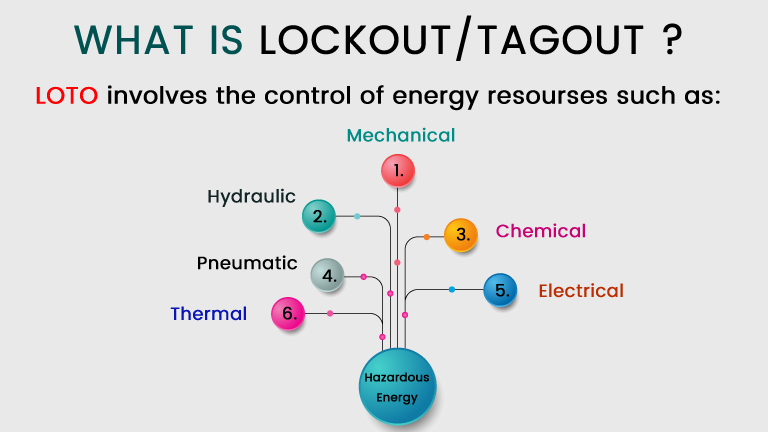

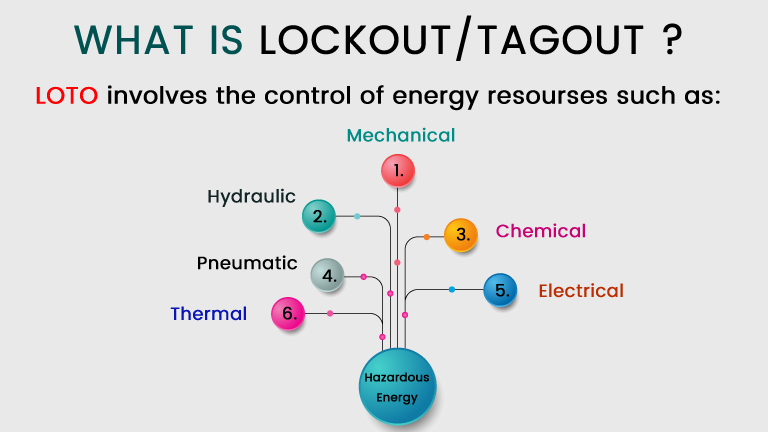

There is one procedure called LOTO (Logout/Tagout) which means no equipment containing hazardous will be back into proper functioning until and unless the hazardous waste has been properly disposed off. These regulations highlight the employer’s responsibility to protect workers from hazardous energy sources, with managers encouraged to develop safety programs that are best suited to their facility. There are many kinds of the Loto Products which help in maintaining the workplace safety for the organization as well as that of the employees of the organization but also in ensuring the ignorance and prevention of various mishaps.

The application of these devices is most common in pipelines where the use of valve is frequent.

(1) Adjustable Ball Valve lockout are the locks fitted on the handles to avoid the escape of the hazardous fluids from the pipe lines.

(2) Valve locking covers are used on the valve having handle made of round shape. These are used to avoid the twisting of the handle of the valve and avoid the flow of the fluid containing element that can harm the environment.

(3) Locks and key safety systems are the system applied where there is a separate room to keep the hazardous waste and used in operating rooms as well as used in FMGC units where safety is considered the top most requirements.

(4) Circuit Breaker locks are used to avoid any accident related to electricity and used where there is complete shut down in the plant.

(5) Hubbell Plugout is the types of locks used particularly on wire having chords attached to it. Chords are nothing but special plug attached to wire to make connection in some electronic devices. The plug outs are used to cover these chords so that the chords are not broken and damaged due to any means as the material used to make chords in plastic which is very harmful for environment as it non bio degradable product.

Conclusion

In all, the loto products with time have proven to be great supporters and helpers when it comes to the safety of the firm and its people. The use of such products should be on a higher note for the sake of individual safety because nothing is more important than the health and safety of any individual be it a worker or the owner of the enterprise. Workplace Safety

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- LOTO KIT

Enquire Now

What Is A Group Lockout Box?

Lockout-Tagout procedure as implemented by OSHA (Occupational Safety and Health Administration) is the best way of securing the workplace and making the workers feel safe and easy. Along with describing the procedure and the necessary LOTO Kit, OSHA’s guidelines highlights the companies which come under their coverage and which don’t. Out of the numerous Lockout Tagout Procedures, one such process is Group Lockout.

Group Lockout-Tagout process is a way of providing the workers a high-level of security. The procedure involves multiple employees working together to perform a service check on a device or machinery which is potentially hazardous and can cause severe damage to the workplace and the employees. The objective is to assign a worker who will overlook the entire process and will be responsible for any mishaps. Also, every worker is required to apply their own Lockout Padlocks to the isolation points on the machine in order to ensure that the device cannot be re-energized until everyone has finished their work and are at safe location. Manufacturer of Lockout Products

For diverse workers, Group Lockout Boxes are used with keys to single or multiple equipments. The keys to lockout devices disconnect master keys which are placed in the Group Lockout Box. Every worker is then required to place his or her own personal lock on the box. When the daily tasks are finished, the worker removes his personal lock. Further the person authorized to supervise the procedure has to verify whether all the personal locks are removed or not. Once the person makes sure all the workers have done their job and are out of the danger zone, he or she reactivates the machinery.

‘Safety House’ manufactures top quality Lockout Tagout Products such as Padlocks, Breaker Kit, Butterfly valves, Lockout Hasp, etc including Group Lockout Boxes which perfectly comply with your requirements.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Know More About Lockout Devices & Their Necessary Criteria

Many industrial accidents happen due to unexpected energisation of machines at workplace. To prevent such accidents from happening and to ensure a safe work environment for the employees, it is important for the organization to implement lockout devices. We at Safety House, the best manufacturer of Lockout Tagout Products in Delhi believe in being well prepared and fostering a culture of safety. There are certain criteria’s that Lockout Tagout Devices must meet before being used by any organization:

a) Lockout devices must be compatible with the work environment they are being used in. Tagout device warnings must remain legible even when they are used in wet, damp, or corrosive conditions.

b) Lockout and tagout devices must be designated by color, shape, or size and must have a standardized print and warning format.

c) The lockout and tagout devices must be really strong so that they can’t be removed inadvertently.

d) Tagout devices must be attached with a single-use, self-locking material such as a nylon cable tie.

e) Whichever employee sees the lockout or tagout device must be able to recognize who attached it and its purpose.

f) Each lock must have a unique key or a combination.

Safety House manufactures the best quality LOTO Products such as cylinder lockout, cable lockout and many more that meet the above necessary requirements.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Checklist For Better Use of Lockout/Tagout Program

Lockout/ Tagout acceptance in your workplace is an essential safety requirement. Preventing the unpredictable accidents of dangerous gasses or energies during service and maintenance ensures the safety of workers and helps to build a productive work environment. Lockout Tagout Products require proper adoption and implementation for workplace and employees. According to a report of Occupational Safety and Health Administration (OSHA), around three million people working with big equipment or machines face the risk of injuries if lockout/ tagout (LOTO) is not properly implemented. This blog post will provide few tips to help your company stay disciplined.

Choose The Right Device: The lockout padlock is one of the important parts of LOTO family. Valves, circuit breakers, switches, etc. are just some of the machines that require lockouts. Sometimes purchasing the right type of lockout may seem overwhelming as these products come in many variants.

Before buying a padlock for your workplace, few things are going to help you a lot:

1. Knowing the exactly right product and use devices verified as per OSHA standard.

2. Make a list of machines that may need lockout devices.

3. Always use standardized goods and tools to keep devices organized.

Lockout Station is an effective way to hold critical devices. This product not only stores important devices, but also they save space, time and efficient operations.

Complete Document Strategy: Lockout implementation needs to be documented by process. This process will help to remove any possible confusion about the ability of management and workers. Documentation also provides employees with valuable training tips. Fixed documentation provided by OSHA is required, given the differences in workplaces and machines, not every Lockout procedure will be the same. It Is very important to make sure the systems are as efficient as possible.

Establish An Attentive Training Program: Careful and thorough training is an essential part of a successful lockout program. All workplaces need to be trained according to their need. It is imperative for each and every worker to his role. Work should be explicitly assigned and defined to the appropriate employee. Strong communication is required to develop among all employees so that they clearly alert affected employees when a lockout device is being placed and removed. Every padlock has a space to write worker’s name.

Careful Evaluation: A careful evolution is a crucial for development. Lockout training and written procedures can be counted as a success, only if they are used in actual maintenance situations. Analysis is important to make sure that the training exercises, procedure, and devices are working properly.

Take a look at LOTO products at www.lockoutindia.com and decide if the products shown on the website will meet all your criteria necessary protect employees while working.

Checkout Our Other Lockout Tagout Products:

- Lockout Hasp

- Group Lockout Box

- Lockout Padlocks

- Valve Lockout

Enquire Now

Electrical Panel Lockout By Top Manufacturer Of LOTO Products

Whether you need them for your manufacturing/ processing plant/ factory, construction site, hospital/ nursing home or hotel, the best manufacturer of Lockout products in Delhi, Safety House makes lockout tagout products for all kinds of businesses/ organisations, as per their requirements. Our wide range of workplace area safety products includes ACB lockout, dielectric padlock, MCB lockout, electrical panel lockout, cylinder lockout and more. (For a complete list of our equipment, visit our LOTO Kit page.)

At Lockout India, we understand your concerns. Our durable products, manufactured in accordance to OSHA standards are reasonably-priced. Last week, we discussed with you our mini lockout station. Today, let us learn about our electrical panel lockout.

1. It allows you to lock out circuit breakers in off position while work is being done.

2. The product prevents unauthorized people from accessing circuit breaker panels. Ensure that an accidental shutdown of critical equipment doesn’t happen.

3. Made of sturdy MS (Mild Steel) sheet, it is available in grey, yellow and red colours. Has a side locking arrangement. (Padlock to be used.)

4. Our electrical panel lockout installs in seconds.

In case of any confusion or queries, drop us an enquiry (Click the blue ‘Contact’ banner on the right side of the website homepage.) and our official would get in touch with you at the earliest.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now