All About Ball Valve Lockout Devices

A work facility is an inexhaustible source of hazardous energy. Energy sources include electrical, hydraulic, mechanical, pneumatic, thermal, etc. and can be detrimental to work forces within the premises. A lot of industrial mishappenings around the world are caused by unexpected energy release and unanticipated equipment startup.ball valve lockout devices

A lockout safety method locks out such energy-isolating devices and ensures that they cannot be operated until the lockout device is removed. It simply aims at improving safety, maintaining compliance and encouraging sustainability. However daunting it might seem, it’s imperative that all the layers of the organization work towards implementing a sustainable lockout safety program. Without seamless cooperation, a lockout system would fall apart.

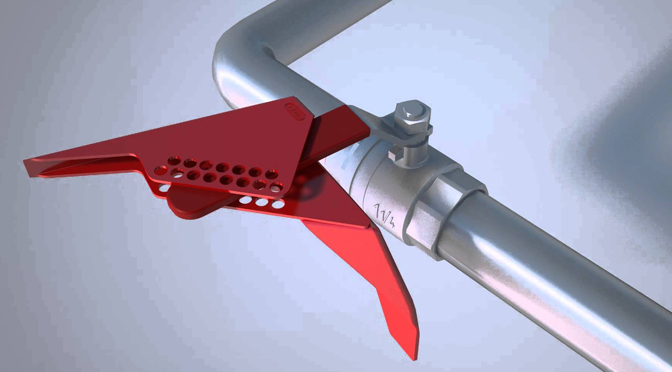

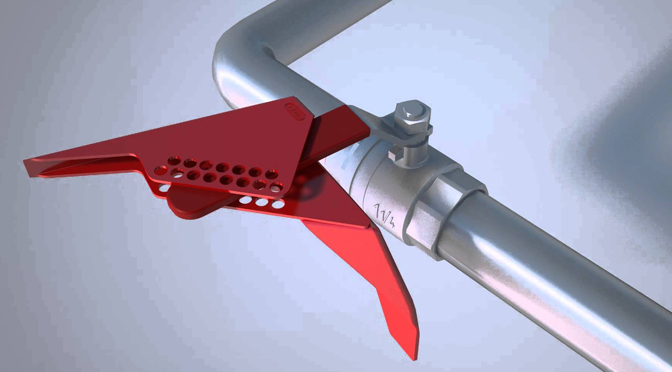

Of all the safety Lockout Tagout Products, today, we’ll discuss about Ball Valve Lockout. Ball Valve is a quarter-turn, straight-through valve that suitably transfers liquids, compressed air, clean gas and slurries (liquids with suspended solids). It uses a hollow and perforated ball to control the flow through it. The ease of operation, repair and versatility that comes with ball valves is what leads to its extensive industrial use. Ball valves have a round closure element that permits consonant sealing stress. Getting its name from the ball that rotates within to close and open the valve, these devices are used where a taut shut-off is required and are a fine source for control applications. Durable and reliable even after jagged use, these safety devices are often preferred to gate and globe valves. Ball valves involve the use of materials such as nylon, delrin, synthetic rubbers and polymers and that imparts an excellent sealing ability. However, there is a potential of wear on the seats and it renders it unsuitable for throttle applications.

Types of Ball Valves:

Valve operation in each type remains the same. The only difference is how these valves are manufactured and assembled. Each design has its own benefits.

– Split body Ball Valve

– Top entry Ball Valve

– End entry Ball Valve

– Double trunnion Ball Valve

– 3-piece Ball Valve

– Lubricated/Non-lubricated Ball Valve

Advantages that a ball valve renders:

– Smooth and straightforward actuation

– Swift opening and closing

– More compact and lighter than a gate valve

– Bubble-tight service

– Wide choices, thus allowing flexibility

– Multi-port designs

– Reliable in high-temperature and high-pressure applications

Used in a variety of applications such as gas processing and storage, fire safe protection services, chlorine manufacturing, and flowing systems, ball valves. Some typical applications are:

– Low point drains in fluid services

– High-point vents in fluid services

– Instrument root valves

– Steam service

– Feed water systems

At Lockout India, it’s all about committing to quality, performance and service. We are the leading manufacturer of various types of Ball Valve Lockout devices and our products satiate different industrial requirements and convincingly control the flow of diverse gases and fluids.

Checkout Our Other Lockout Tagout Products:

- Lockout Kit

- Group Lockout Box

- Lockout Station

Enquire Now

Safety House Loto Products For Safe Work Environment

What is a Lockout/Tag out?

The logout/tag out is abbreviated as LOTO these are practices and procedures are now a days a very common practice which means shutting off the dangerous machines which contains hazardous waste like lubricating oils, smoke and degradable products which may harm the environment and not able to start them until and unless completion of maintenance or servicing work is done.Safety House Loto Products

While servicing is done hazardous energy is isolated and inoperative because if this hazardous waste is let free in the air might create a severe problem. After the service is done the service man hen locked and a tag is placed on the lock identifying the worker who has placed it which again states that this practice is a useful and safe practice for both the employee and environment as well. There are special devices designed and applied according to the nature of hazardous energy and nature of use which does not allow disposing of this hazardous waste into the open air. All these devices have the main motive of ensuring the workplace safety of all the individuals who are working under the organization.

There are various kinds tag out devices which can be used depending on the needs and interests of the hiring organizations and firms. Below stated are some different types of lockout devices with the name and nature of its use.

(1) Adjustable Ball valve locks are the most prominent devices used now a days in industry because they are easy to install and does not allow the easy disposed off the fluids nature of molecule as the application is the most simplest of all the tag out devices.

(2) Valve Lockouts are kind of caps which are placed on the rotating type valves, these are very easy to install and effective when in use.

(3) Safety Locks as the name suggest are the simple locks used at the storage areas where the hazardous waste is kept off to lock some operating rooms which are not in use of a room where the entry in only done when a person is able to fulfil the safety parameters as per required.

(4) Hubell Plugout used where the wires with plugs in front and the wires are not in use for some time. These are used to avoid the damage of the plug and as the material of the plug are plastic which may lead to damaging the environment as well.

(5) Circuit breaker lockout as the name suggest these are used where the electrical panel is installed and these helps in achieving operator safety.

Conclusion

There are many more which can be used but some of the basic tag out or lockout devices for the workplace safety are jotted down in the information stated above. Hence, we can conclude by remarking that the tag out devices can be used for the betterment of the environment of any organization as well as the proper safety of the employees working in that particular firm too.Safety House Loto Products

Checkout Our Other Lockout Tagout Products:

- Valve Lockout

- MCB Lockout

- Lockout Padlocks

Enquire Now

Never Ignore Workplace Safety

If we say that a belonging can come in a working environment that can only be achieved or attained by keeping the employee safe, if a employee is not safe or does not have safe working environment he/she will never be happy will not religiously work for you and may commit mistakes while working, the mistake can go up to that extent that a working operator can meet with a sever accident and can lead death. Workplace Safety

Definition of Safety

Safety as the word suggest means creating safe working environment like having sufficient amount of light while doing so critical work, optimum exhaust openings while doing some job which may include use of hazardous effluents, use of gloves while working on machines, use of helmet when working on height, wearing shoes when in workshops. Ergonomics is also considered as one of the most important part of occupational health and safety as a proper layout is made and the execution is laid accordingly helps in reducing the chances of workers fatigue. This applies not only to those working on computer workstations but also to those using equipment which are controlled from one place. The principles of ergonomics apply to all workers who spend hours sitting in the same position.

There is one procedure called LOTO (Logout/Tagout) which means no equipment containing hazardous will be back into proper functioning until and unless the hazardous waste has been properly disposed off. These regulations highlight the employer’s responsibility to protect workers from hazardous energy sources, with managers encouraged to develop safety programs that are best suited to their facility. There are many kinds of the Loto Products which help in maintaining the workplace safety for the organization as well as that of the employees of the organization but also in ensuring the ignorance and prevention of various mishaps.

The application of these devices is most common in pipelines where the use of valve is frequent.

(1) Adjustable Ball Valve lockout are the locks fitted on the handles to avoid the escape of the hazardous fluids from the pipe lines.

(2) Valve locking covers are used on the valve having handle made of round shape. These are used to avoid the twisting of the handle of the valve and avoid the flow of the fluid containing element that can harm the environment.

(3) Locks and key safety systems are the system applied where there is a separate room to keep the hazardous waste and used in operating rooms as well as used in FMGC units where safety is considered the top most requirements.

(4) Circuit Breaker locks are used to avoid any accident related to electricity and used where there is complete shut down in the plant.

(5) Hubbell Plugout is the types of locks used particularly on wire having chords attached to it. Chords are nothing but special plug attached to wire to make connection in some electronic devices. The plug outs are used to cover these chords so that the chords are not broken and damaged due to any means as the material used to make chords in plastic which is very harmful for environment as it non bio degradable product.

Conclusion

In all, the loto products with time have proven to be great supporters and helpers when it comes to the safety of the firm and its people. The use of such products should be on a higher note for the sake of individual safety because nothing is more important than the health and safety of any individual be it a worker or the owner of the enterprise. Workplace Safety

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- LOTO KIT

Enquire Now