Electrical Panel Lockout Switches With Safety

Electrical Panel as the name suggests are the systems which distribute the units of electricity to various electricity circuits due to which the other name is given to electrical panel that is distribution board. These panels are in robust in construction, rectangular in shape and vary in sizes according to the type of system which is to be imparted in the organization. When these Electrical panel lockout are not in use from the safety point of view lockout devices are used to avoid any miss happening to take place or any accident to occur which may lead to sudden death of any individual due to electrical shocks.

The Lockout devices that are very common now days and used in many industries for the purpose of safety are being described in the information stated below.

(1) MCB (Miniature Circuit Breaker) / Circuit Breaker Lockout Device very common lockout device, prevents the circuit breaker toggle from being turned on. It is then fit with an appropriate padlock to prevent unauthorized removal.

(2) Electrical Panel Lockout Device as the name suggest device with tough, lightweight, dielectric thermoplastic bodies that completely enclose the electrical plug thus protecting against accidental reconnection.

(3) Pendant Lockout device is used to lock large electrical connectors and control the hoist.

(4) Electrical Panel Lockout is used on switches where there is no inbuilt lockout provision. They consist of removable push button and rotary switch covers, which is secured with a padlock or hasp and this cover prohibits access to a switch or control on the electrical panel. They use transparent bases and cover that allow visibility of nameplates and labels.

(5) Panel Lockout is rectangular strip which is attached to the panel cover and the rectangular strip is encapsulated by the device preventing the panel cover from being removed. The circuit breakers remain locked off while work is being done. The Panel Lockout comes with a brass padlock and reusable tagout. Panel Lockout can also be used to prevent accidental shutdowns of critical equipment by keeping unauthorized persons from accessing electrical circuit breaker panels, security panels, and data centre panels and associated pull boxes.

(6) Electrical panel lockout with square base these are covering provided on the electrical button which is spring operated, these are used to avoid accidentally pressing the button.

The Lockout Tagout Products are a great way to ensure the workplace safety of the organizations as well as the individuals. There are many world pioneers in lockout/ tagout items and administrations that offer a wide scope of strong, simple to-utilize lockout gadgets that cover most mechanical and electrical applications. Many of them cover the other basic parts of an agreeable, viable vitality control program by giving imaginative answers for preparing workers, making reported methodology, and recognizing vitality sources. Many of these devices help various kinds of organizations with restricted assets rapidly get their program up to speed, guaranteeing that lockout exercises are executed in a way that advances ideal well-being while augmenting productivity and lessening downtime.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Hasp

Enquire Now

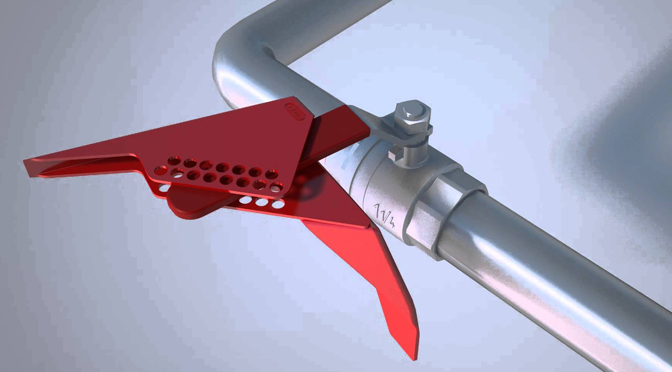

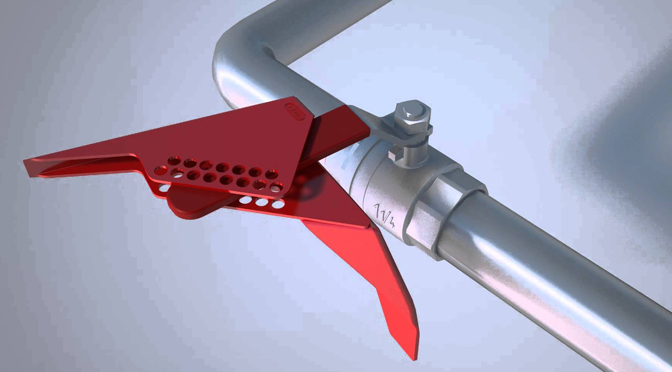

All About Ball Valve Lockout Devices

A work facility is an inexhaustible source of hazardous energy. Energy sources include electrical, hydraulic, mechanical, pneumatic, thermal, etc. and can be detrimental to work forces within the premises. A lot of industrial mishappenings around the world are caused by unexpected energy release and unanticipated equipment startup.ball valve lockout devices

A lockout safety method locks out such energy-isolating devices and ensures that they cannot be operated until the lockout device is removed. It simply aims at improving safety, maintaining compliance and encouraging sustainability. However daunting it might seem, it’s imperative that all the layers of the organization work towards implementing a sustainable lockout safety program. Without seamless cooperation, a lockout system would fall apart.

Of all the safety Lockout Tagout Products, today, we’ll discuss about Ball Valve Lockout. Ball Valve is a quarter-turn, straight-through valve that suitably transfers liquids, compressed air, clean gas and slurries (liquids with suspended solids). It uses a hollow and perforated ball to control the flow through it. The ease of operation, repair and versatility that comes with ball valves is what leads to its extensive industrial use. Ball valves have a round closure element that permits consonant sealing stress. Getting its name from the ball that rotates within to close and open the valve, these devices are used where a taut shut-off is required and are a fine source for control applications. Durable and reliable even after jagged use, these safety devices are often preferred to gate and globe valves. Ball valves involve the use of materials such as nylon, delrin, synthetic rubbers and polymers and that imparts an excellent sealing ability. However, there is a potential of wear on the seats and it renders it unsuitable for throttle applications.

Types of Ball Valves:

Valve operation in each type remains the same. The only difference is how these valves are manufactured and assembled. Each design has its own benefits.

– Split body Ball Valve

– Top entry Ball Valve

– End entry Ball Valve

– Double trunnion Ball Valve

– 3-piece Ball Valve

– Lubricated/Non-lubricated Ball Valve

Advantages that a ball valve renders:

– Smooth and straightforward actuation

– Swift opening and closing

– More compact and lighter than a gate valve

– Bubble-tight service

– Wide choices, thus allowing flexibility

– Multi-port designs

– Reliable in high-temperature and high-pressure applications

Used in a variety of applications such as gas processing and storage, fire safe protection services, chlorine manufacturing, and flowing systems, ball valves. Some typical applications are:

– Low point drains in fluid services

– High-point vents in fluid services

– Instrument root valves

– Steam service

– Feed water systems

At Lockout India, it’s all about committing to quality, performance and service. We are the leading manufacturer of various types of Ball Valve Lockout devices and our products satiate different industrial requirements and convincingly control the flow of diverse gases and fluids.

Checkout Our Other Lockout Tagout Products:

- Lockout Kit

- Group Lockout Box

- Lockout Station

Enquire Now

Keeping the work facility safe: A guide for employers

General industry workers who service and maintain the machineries are exposed to unexpected energization, startup and release of hazardous energy. The work practices can prove to be fatal if proper safety measures aren’t followed. This is where OSHA heavily focuses. OSHA’s standard 1910.147 is all about the control of hazardous energy (lockout/tagout) and requires energy control procedures for all the machines that are prone to dysfunction and could be a source of mechanical/chemical/thermal/hydraulic energy outburst.

Who has the ultimate responsibility to implement lockout safety procedure within a facility? This is perhaps the most-asked question. OSHA requires the employers to take proper steps against unexpected machinery startup and energy outbursts. But simply buying the Lockout Tagout Products is not enough. Most of the firms fall short on enabling effective procedures and fast action by employees. They do not have a set of machine-specific instructions and these instructions are generally not handy to the employees.

Follow the below mentioned steps and ensure a consistent and effective lockout safety program:

– Communication is the key: Communicate to your employees the benefits of an effective lockout program. It is your duty to instill in your employees the value of a safe working environment. Also, produce an easy-to-use set of guidelines that your employees understand.

– Make a complete list of machinery that might require lockout safety procedures. It is also important to keep your equipments in a healthy state with timely maintenance and repairs.

– Identify the energy points and label the isolation devices (valves and breaker panels).

– List and document the hardware that might be needed for to lock out and isolate machinery and equipment. Devices such as padlocks and tags.

– There’s no generic safety procedure. Make sure you document machine-specific procedures and specific steps to isolate, secure and shut it down.

– Implement comprehensive training sessions and make sure the employees have a clear understanding of safety procedures and the magnitude of hazardous energy sources within the facility.

– Sort out your workers according to their lockout responsibilities. Anyone unaware of the health hazards and safety procedure shouldn’t be allowed near the machineries but still must receive basic instructions regarding energy control. As an employer, it is your responsibility to protect all the workers.

And lastly, keep reviewing and updating your safety program. Just like machinery, a lockout safety program requires periodic reviews.

Checkout Our Other Lockout Tagout Products:

- Valve Lockout

- MCB Lockout

- Lockout Padlocks

Enquire Now

Best Ways To Avoid Conflict With OSHA

It is said that smart people are those who learn from their own mistakes. But smartest are the ones who learn from the mistakes committed by others. Today we bring you a very interesting blog regarding how you can avoid getting in trouble with OSHA (Occupational Safety and Health Administration). manufacturer of lockout products

It has happened numerous times when industrial men won’t listen to OSHA and completely ignore their prescribed guidelines of implementing Lockout Tagout system in order to secure the workplace and the life of the staff employed. This often leads to conflicts with the supervising establishment and it is advisable to never disrespect your bread and butter. Reason being OSHA has the right to shut down a firm or extricate the employed staff from the organizations where the guidelines aren’t followed.

So, if you want to steer clear of facing any kind of trouble with OSHA and wish to eschew any catastrophic accident happening in your organization, keep note of the following things: –

Ensure your Lockout-Tagout practices are appropriate to the way they are prescribed in OSHA’s guidelines to safeguard the employees against possible injuries such as amputations, or even death. Always ask OSHA for any query if you may have any.

Always report about damaged or missing guards and never ever bypass a moving device. Until and unless the damaged machinery is repaired or replaced, make sure all of your workers are taking necessary precautions.

Update yourself with all the MSDS information of the chemicals that are used by you and your employees on site. Ensure you are providing protective workshops and training to the staff.

Considering most of the injuries happen due to lack of safety operating procedures, deficient safety-rule and inadequate training given to employees, always make sure your establishment never falls into any of these three categories.

Learn to use cords flexibly. Practice running extension cords overhead or taping them down to avoid tripping.

It is hard to keep track of all the safety guidelines prescribed by OSHA so at least by adhering to the above mentioned techniques, you can hope for a secure workplace and obviously manage to keep OSHA away from raining down on you. For more relevant information regarding Lockout-Tagout procedure, stays tuned to our blog and if interested in purchasing LOTO Kit, feel free to order online because we are the best Lockout-Tagout product manufacturer in India.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

An Insight Into OSHA Violations

While there is no Indian equivalent of OSHA, i.e., Occupational Safety and Health Administration, the United States federal agency that works towards assuring safe working conditions across US, OSHA guidelines are used the world over as benchmarks of workplace area safety. Year after year, the agency of the US Department of Labor releases a list of top ten most cited violations that it comes across during safety inspections across the country. Today, on the blog of the top manufacturer of LOTO products in India, i.e. Safety House, we discuss some of these violations, that feature in subsequent lists. Remember, these are in no particular order.

1: This is concerned with chemical safety at workplaces. Of prime importance is the fact that hazards by chemicals must be identified, and available to/ understood by workers. Signs and right-to-know placards should be used.

2: Employers must provide fall protection systems. Like all other points, this is vast, but employees need to determine if walking surfaces have the strength to support employees. Walking surfaces that are over 6 feet above a lower level must be protected through guardrail.

3: Appropriate LOTO devices must be used to prevent unexpected energization/ release of stored energy from machines.Equipment must be tested to verify the effectiveness of lockout tagout products and other energy control measures.

To Continue Click Here

Checkout Our Other Lockout Tagout Products:

- Lockout Hasp

- Group Lockout Box

- Lockout Station

- Valve Lockout

Enquire Now

10 Safety Violations At Your Work

Posted On: January 23, 2016

Categorized In: Safety / Security

Written By: Lockout India

“What’s a workplace without safety?” All the equipments we use at home are produced by machines. With people – supervisors, workers, engineers working around these machines, the issue of ‘safety’ comes into mind. Despite warnings and cautions, every year thousands of people are injured or die due to certain violations.

Violations – Safety violations refer to those infringements that are easily avoidable by following some basic steps. These violations are measured on standards set by Occupational Safety & Health Administration (OSHA). Violations occur ‘due to negligence’ or sometimes unintentionally. manufacturer of lockout products

10 Workplace Safety Violations

1. Fall Protection

This is the most frequent violation that takes place. The workers need to be provided with standard equipments like toe boards, guard rails & safety nets that prohibit ‘falling’ from heights.

2. Hazard Communication

Workers need to be identified with the chemicals they are going to interact with. The chemical importers/manufacturers need to specify the hazards caused by the chemicals they provide through packet labels and data sheets.

3. Scaffolding

This is a construction standard violation which means accidents caused by ‘faults’. The temporary support created for construction might ‘slip’ due to weak foundation or a worker might slip. This also involves employees stuck by falling objects, faulty scaffold design – connecting hardware, load capacity and suspension rope.

4. Respiratory Protection

The workers need to wear respirators to protect themselves against insufficient oxygen supply, harmful dusts, smokes, sprays & gases. Industries produce the worst of air components. These hazards might cause cancer, breathing problems and in worst cases death.

5. Lockout/Tag out

\Machines might unexpectedly start or release stored energy like electrical, thermal, pneumatic or hydraulic during maintenance & service breaks. These are easily preventable by following the ‘OSHA safety protocols’ i.e. the LOTO safety procedure.

6. Powered Industrial Trucks

The use of heavy lifting machines like mini-cranes, forklifts, platform lift trucks, motorized hand trucks and other fuel & electricity powered trucks could cause serious injuries to workers. The breaches here are: false truck identifications, in-experienced drivers, under-age workers in the trucks, un-certified equipments etc.

7. Ladders

Industrial ladders are tall, unstable & uncomfortably placed there by posing major challenges to workers. The fall or slippage could harm the workers badly. Hence, it is the duty of managers to ensure the ladder’s efficiency.

8. Machine Guarding

Moving machine parts like saws and presses could cause lacerations & burns killing workers. Therefore, all moving machines are required to be safeguarded at all times. Managers/workers must ensure that the stoppers/guards never come off.

9. Electrical – Wiring Methods

Wiring safety is necessary for every worker. Wiring methods include installation of electrical tools in the specified and safety-insured manner. Every step of wiring process like conductors, grounding, insulation or installations should be done with adequate caution by an expert.

10. Electrical – General Requirements

It covers overall safety regulations mainly on new installations. The common defiance’s include mechanical strength, safeguards, equipment durability, connection space, electrical enclosures etc. Only a professional should follow the procedures.

Safety is a ‘serious’ issue which is why Lockout India creates products that ensure safety and follow OSHA’s safety guidelines. The safety equipments of the given violations are available at our store. Plus we have a mammoth set of safety products to ensure complete protection.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Workplace Safety – The Introduction

Posted On: December 31, 2015

Categorized In: Safety / Security

Written By: Lockout India

Welcome to Lockout India. In this post which is our first, we will try and evaluate the basics of workplace safety, what we do & how we can help. The aspect of workplace safety we are talking about is the hazards caused by machines. A concept called “Energy Isolation” persists to verify the protocols. So what are the hazards? Who takes care of the procedure? What do we do? All your questions will be answered here. The hazard safety is an issue strictly limited to industries and factories. manufacturer of lockout products

What are the Hazards?

Hazards are provoked by energy. Since, all industrial machines require energy of some type (electrical, hydraulic, kinetic etc.), during service breaks and maintenance works; the machines need to be shut-off completely. However, machines running on power could start without warning (unexpectedly) or release the residual energy. Such instances could and have lead to fatal injuries and death of workers.

Some hazardous injuries are: Body fracture, Electrocution, Burns, Cutting, Crushing, Amputations etc. The fatality of the injury depends on the amount of pressure the machine dictates. This is to be avoided in any circumstance using the safety protocols.

The Safety Protocols

In an Ezine Article, we have given a sight into the Energy Isolation process. The safety procedure is known as LOTO procedure (Lockout- Tag out). OSHA also known as Occupational Safety & Health Administration is a prime organization of the United States Department of Labor whose aim is to ‘ensure a safe & healthy environment for workers enforced by certain standards. OSHA includes some definitions and gives out measures to be implemented during Energy Isolation.

Our Inclusion

Lockout India understands the importance of workplace safety and hence develops a wide range of products to fulfill that aim. All our Lockout Tagout products are CE certified that fit OSHA’s safety standards perfectly. Also, one other thing that has not been mentioned above is Tag out. Tag out means stamping a machine as closed. The “Warning” tag put up involves the person’s name, reason for tag and time. Also, some other types of tags are also included like ‘Danger’ tag, ‘do not start’ tag & ‘closed’ tag.

Our Products

Take a look at our extensive range of products. There are solutions for everything. There are group lockout boxes, hasps, valves, MCB lockouts, key cabinets, isolation padlocks, circuit breakers etc. Just scroll the pages or find your product with the advanced search option, add multiple products into the cart and get going with proofing your workplace.

Our aim apart from providing safety-insured products is “Customer Satisfaction”. By providing everything that the customer wants with his/her utmost satisfaction would make us proud. Stay tuned!

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now