Keeping the work facility safe: A guide for employers

General industry workers who service and maintain the machineries are exposed to unexpected energization, startup and release of hazardous energy. The work practices can prove to be fatal if proper safety measures aren’t followed. This is where OSHA heavily focuses. OSHA’s standard 1910.147 is all about the control of hazardous energy (lockout/tagout) and requires energy control procedures for all the machines that are prone to dysfunction and could be a source of mechanical/chemical/thermal/hydraulic energy outburst.

Who has the ultimate responsibility to implement lockout safety procedure within a facility? This is perhaps the most-asked question. OSHA requires the employers to take proper steps against unexpected machinery startup and energy outbursts. But simply buying the Lockout Tagout Products is not enough. Most of the firms fall short on enabling effective procedures and fast action by employees. They do not have a set of machine-specific instructions and these instructions are generally not handy to the employees.

Follow the below mentioned steps and ensure a consistent and effective lockout safety program:

– Communication is the key: Communicate to your employees the benefits of an effective lockout program. It is your duty to instill in your employees the value of a safe working environment. Also, produce an easy-to-use set of guidelines that your employees understand.

– Make a complete list of machinery that might require lockout safety procedures. It is also important to keep your equipments in a healthy state with timely maintenance and repairs.

– Identify the energy points and label the isolation devices (valves and breaker panels).

– List and document the hardware that might be needed for to lock out and isolate machinery and equipment. Devices such as padlocks and tags.

– There’s no generic safety procedure. Make sure you document machine-specific procedures and specific steps to isolate, secure and shut it down.

– Implement comprehensive training sessions and make sure the employees have a clear understanding of safety procedures and the magnitude of hazardous energy sources within the facility.

– Sort out your workers according to their lockout responsibilities. Anyone unaware of the health hazards and safety procedure shouldn’t be allowed near the machineries but still must receive basic instructions regarding energy control. As an employer, it is your responsibility to protect all the workers.

And lastly, keep reviewing and updating your safety program. Just like machinery, a lockout safety program requires periodic reviews.

Checkout Our Other Lockout Tagout Products:

- Valve Lockout

- MCB Lockout

- Lockout Padlocks

Enquire Now

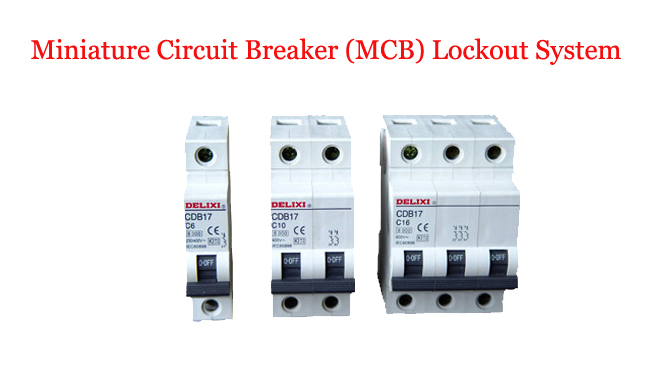

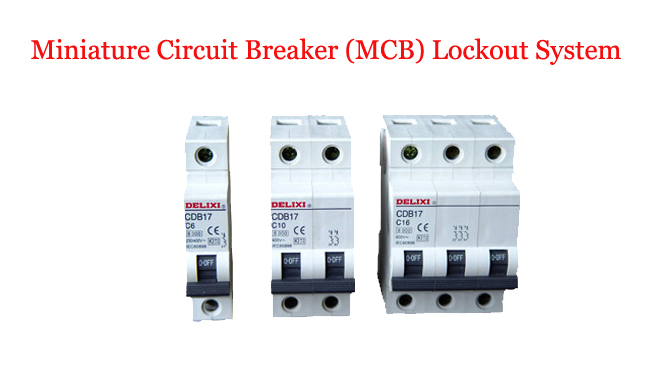

Miniature Circuit Breaker (MCB) Lockout System

A fuse, as we all know, needs to be replaced once operated. These days, most of the circuits come with an alternative and that is a Miniature Circuit Breaker (MCB). An MCB Lockout is an electromagnetically device which operates as an automatic switch and protects an electrical circuit from damage caused by excess current or overheating, generally caused by a short-circuit or a faulty design. Unlike a fuse, when an overload is detected, an MCB doesn’t have to be replaced. It can be reset, either manually or automatically and continue to function and thus offers an improved functioning and operational safety without additional costs. In a nutshell, an MCB functions as a switch that automatically turns off when the flowing current passes the allowed limit.

A miniature circuit breaker comprises of two contacts, fixed and moveable. A solenoid forces the moveable contact to disconnect from the fixed one whenever the current exceeds the allowed limit, thereby stopping the current flow through the circuit. This mechanism protects from current over load. However, a bi-metallic strip is used to protect from overheating and increase in temperature. The overload causes the temperature to rise and subsequently, the bi-metallic strip heats and deflects. The deflection then releases the trip latch and separates the contacts.

Miniature circuit breakers serve two purposes. They function as a fuse and as a switch. By toggling the switch to the ‘off’ position, the circuit can be opened for safety and maintenance purposes. Before the maintenance process begins, miniature circuit breakers need to be locked and tagged out. This ensures that they are not accidentally reactivated while maintenance is still in process.

While there are numerous companies dealing in lock out devices, Lockout India manufactures safe, effective and reliable universal miniature circuit breakers lockout devices that work on most circuit breakers throughout the world. They comply with OSHA’s safety standard 1910.147 and ensure that electrical energy sources are locked out for optimum work safety. These lockout devices are manufactured using durable plastics and effectively lock out the circuit breakers. These can be used for single, double, triple and quadruple pole MCB and can be easily installed using a screwdriver.

Checkout Our Other Lockout Tagout Products:

- MCB Lockout

- Lockout Padlocks

- Scaffold Tag

Enquire Now

Control Heavy Electricity Flow at Your Workplace

Lockout and Tagout have been widely used by almost every small and large companies across the world to insure safety of their employees or workplace. A large range of LOTO products for preventing any kind of accident at work place and Circuit Breaker Lockout is one of them. Circuit Breaker system are specially designed to protect electrical circuits from damage caused by overload or short circuit. Control Heavy Electricity Flow

To detect the fault condition and open the circuit automatically when there is a fault is the basic function function of a circuit breaker. It is usually used as a manual energy- isolation device by manually placing it in the OFF position. Circuit Breaker system can be of any size and shape. So we will tell you about different types of Circuit Breaker Systems.

1. Types of Circuit Breaker Lockouts

2. Pin Type Circuit Breaker lockout

3. Miniature Circuit Breaker Lockout

4. Large Circuit Breaker Lockout

5. Universal Circuit Breaker Lockout

6. Circuit Breaker Lockout Kits

7. 480-600 V Breaker Lockout

8. Wall Switch Lockout

The Circuit Breaker Lockout has been designed to lockout little circuit breakers and therefore prevent accidental switch on. These devices works with all Lockout Safety padlocks and most hasps.

Instructions For Use

1. Switch “OFF” the circuit breaker handle

2. Place the lockout over the handle

3. Tighten the set screw by hand, rotate the toggle

4. Apply a lockout padlock

5. Make sure the switch is completely locked out and cannot be energized until the lockout device is removed.

Lockout India is a manufacturer of lockout products. They manufacture Lockout Tagout Products under OSHA standard.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now