Checklist For Better Use of Lockout/Tagout Program

Lockout/ Tagout acceptance in your workplace is an essential safety requirement. Preventing the unpredictable accidents of dangerous gasses or energies during service and maintenance ensures the safety of workers and helps to build a productive work environment. Lockout Tagout Products require proper adoption and implementation for workplace and employees. According to a report of Occupational Safety and Health Administration (OSHA), around three million people working with big equipment or machines face the risk of injuries if lockout/ tagout (LOTO) is not properly implemented. This blog post will provide few tips to help your company stay disciplined.

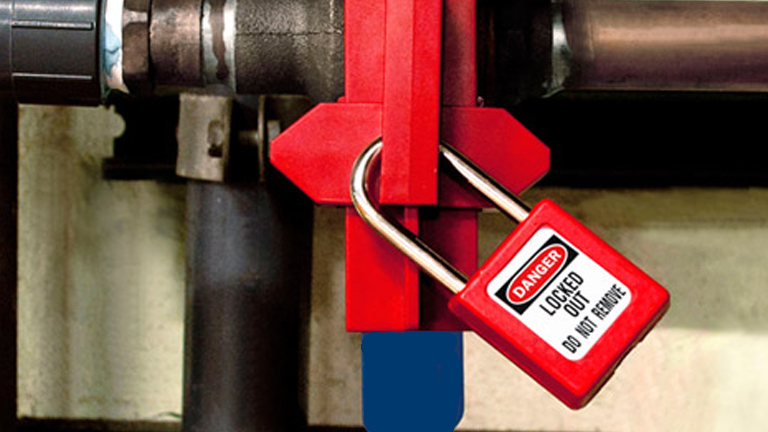

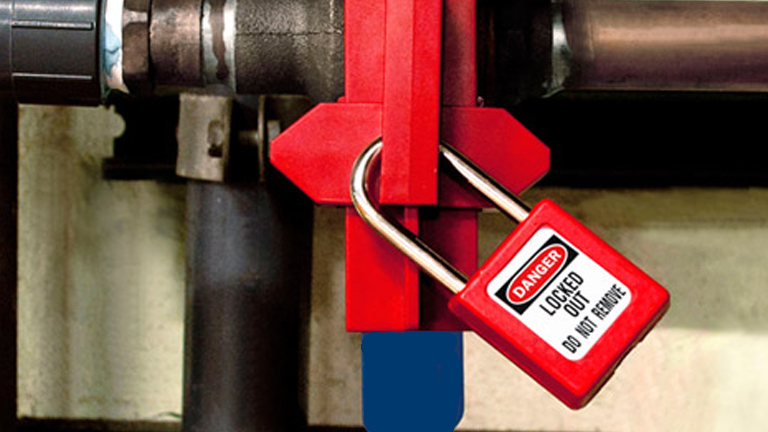

Choose The Right Device: The lockout padlock is one of the important parts of LOTO family. Valves, circuit breakers, switches, etc. are just some of the machines that require lockouts. Sometimes purchasing the right type of lockout may seem overwhelming as these products come in many variants.

Before buying a padlock for your workplace, few things are going to help you a lot:

1. Knowing the exactly right product and use devices verified as per OSHA standard.

2. Make a list of machines that may need lockout devices.

3. Always use standardized goods and tools to keep devices organized.

Lockout Station is an effective way to hold critical devices. This product not only stores important devices, but also they save space, time and efficient operations.

Complete Document Strategy: Lockout implementation needs to be documented by process. This process will help to remove any possible confusion about the ability of management and workers. Documentation also provides employees with valuable training tips. Fixed documentation provided by OSHA is required, given the differences in workplaces and machines, not every Lockout procedure will be the same. It Is very important to make sure the systems are as efficient as possible.

Establish An Attentive Training Program: Careful and thorough training is an essential part of a successful lockout program. All workplaces need to be trained according to their need. It is imperative for each and every worker to his role. Work should be explicitly assigned and defined to the appropriate employee. Strong communication is required to develop among all employees so that they clearly alert affected employees when a lockout device is being placed and removed. Every padlock has a space to write worker’s name.

Careful Evaluation: A careful evolution is a crucial for development. Lockout training and written procedures can be counted as a success, only if they are used in actual maintenance situations. Analysis is important to make sure that the training exercises, procedure, and devices are working properly.

Take a look at LOTO products at www.lockoutindia.com and decide if the products shown on the website will meet all your criteria necessary protect employees while working.

Checkout Our Other Lockout Tagout Products:

- Lockout Hasp

- Group Lockout Box

- Lockout Padlocks

- Valve Lockout

Enquire Now