Understanding Scaffold Tag Colors: Green, Yellow, and Red Explained

Introduction to Scaffold Tagging

Scaffold tag are a critical component of workplace safety, providing clear visual indicators about the condition and usability of scaffolding on construction sites. These tags serve as quick reference points for workers, supervisors, and safety officers, helping prevent accidents and ensure compliance with safety regulations.

Color-coded scaffold tags play an essential role in this system. By quickly identifying the status of a scaffold through a simple color system, workers can make informed decisions about whether a scaffold is safe to use, needs caution, or must be avoided entirely. At Safet House Loto, we emphasize the use of scaffold tags as part of a broader safety strategy, complementing Lockout Tagout devices to maintain a safe working environment.

The Meaning of Green Scaffold Tags

A green scaffolding tag is the universal signal for safety. When you see a green tag, it indicates that the scaffold has passed all inspections and is considered safe for use.

Criteria for issuing a green tag include:

- Completion of a thorough scaffolding inspection.

- No visible defects or structural issues.

- Confirmation that all components meet regulatory safety standards.

Maintaining a green status requires regular inspections. Workers and supervisors should ensure scaffolds are checked frequently, particularly after adverse weather conditions, modifications, or heavy use. These inspections help keep the site safe and reinforce a culture of accountability.

Tip: Pairing scaffold tags with proper documentation ensures that everyone on-site is aware of scaffold safety status, reducing the likelihood of accidents.

The Meaning of Yellow Scaffold Tags

Yellow scaffold tags indicate caution or restricted use. These tags alert workers that while the scaffold may be usable, it has minor issues that require attention.

Common reasons scaffolds receive yellow tags include:

- Loose or missing components that do not immediately compromise safety.

- Scaffolds requiring minor maintenance or adjustments.

- Temporary structural concerns that need monitoring.

When encountering a yellow-tagged scaffold, workers should:

- Review the scaffold inspection notes carefully.

- Limit the load or use of the scaffold as instructed.

- Report any changes in condition immediately to supervisors.

Yellow tags are an early warning system. They allow work to continue safely while addressing minor issues before they escalate into major hazards. At Safet House Loto, using scaffolding inspection tags ensures everyone is aware of these cautions in real time.

The Meaning of Red Scaffold Tags

Red scaffold tags signal danger. A scaffold with a red tag must not be used under any circumstances.

Conditions that typically lead to a red tag include:

- Structural failure or major damage.

- Unsafe assembly or missing critical components.

- Exposure to environmental hazards that compromise integrity.

Procedures to follow for red-tagged scaffolds:

- Restrict access immediately and ensure all personnel are informed.

- Document the scaffold’s condition clearly.

- Schedule repairs or dismantling before resuming any work.

Red tags act as a critical safety checkpoint. Ignoring a red tag can result in serious injuries or fatalities, highlighting why scaffolding tags are indispensable in workplace safety programs.

How Scaffold Tag Colors Enhance Workplace Safety

Using green, yellow, and red scaffold tags significantly improves safety outcomes on construction sites:

- Preventing accidents and injuries: Clear visual indicators allow workers to make informed decisions and avoid hazardous scaffolds.

- Promoting regulatory compliance: Scaffold tags align with OSHA and other occupational health standards, ensuring proper safety procedures are followed.

- Efficient communication: Tags serve as an instant, universal language, reducing confusion and increasing accountability.

By integrating scaffold tags with Lockout tagout devices, companies like Safet House Loto create a layered safety system that protects both workers and equipment.

Best Practices for Scaffold Tagging

To maximize the effectiveness of scaffold tags, follow these best practices:

- Regular inspections and documentation: Conduct frequent checks and record the status of scaffolds to maintain safety transparency.

- Training workers: Ensure all personnel understand the meaning of each color-coded tag and how to respond appropriately.

- Coordination with supervisors and safety officers: Effective communication ensures issues are resolved promptly and safely.

Proper use of scaffolding inspection tags not only protects workers but also improves operational efficiency by preventing downtime caused by unsafe scaffolds.

Conclusion

Scaffold tags—green, yellow, and red—are essential tools for maintaining safety on construction sites. They provide clear, visual communication about scaffold status, helping prevent accidents and ensuring compliance with safety regulations.

At Safet House Loto, we emphasize the importance of scaffold tags, alongside Lockout products, to create a safer work environment. By consistently using and understanding scaffold tags, workers can confidently navigate construction sites while minimizing risk.

Remember, safety starts with awareness. Understanding and respecting scaffold tags is a simple but powerful way to protect lives and maintain operational efficiency.

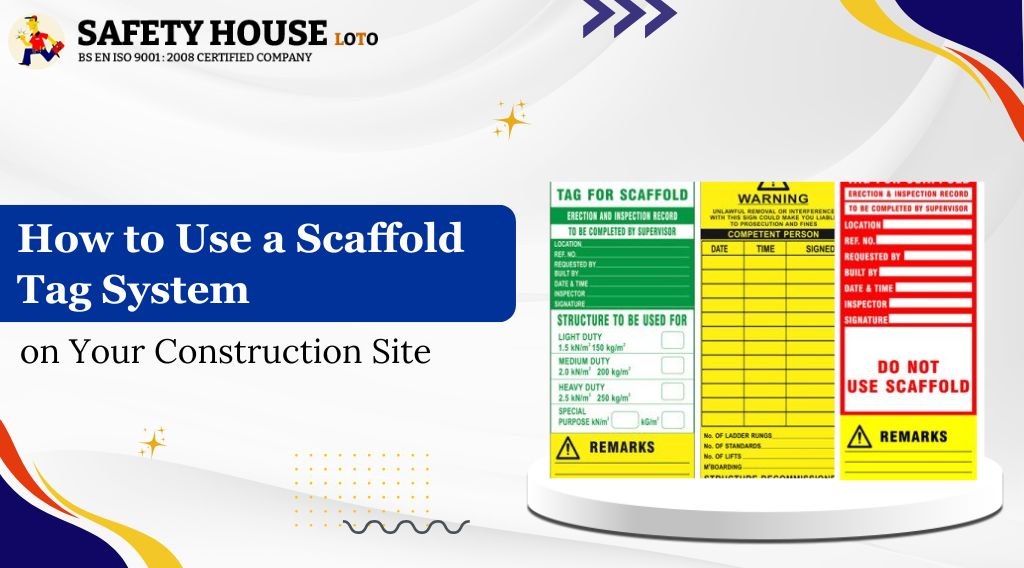

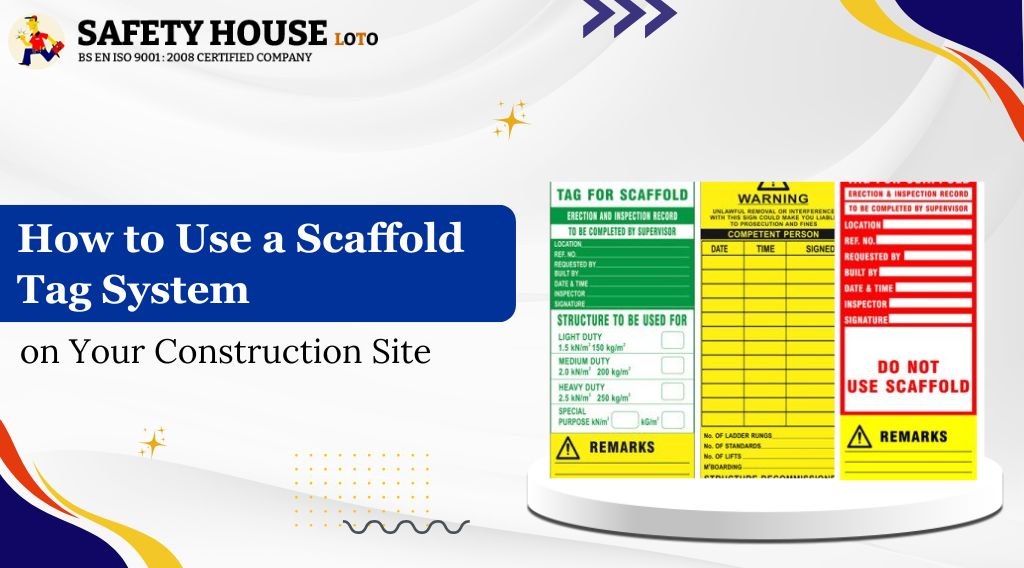

How to Use a Scaffold Tag System on Your Construction Site

Construction sites are inherently dangerous environments where worker safety must remain the top priority. Among the various safety protocols, implementing an effective scaffold tag system stands as one of the most critical measures for preventing accidents and ensuring regulatory compliance. When combined with proper lockout/tagout (LOTO) procedures, these systems create multiple layers of protection that can save lives.

Understanding Scaffold Tags and Their Importance

A scaffold tag serves as a visual communication tool that instantly conveys the safety status of scaffolding structures. These tags eliminate guesswork and provide clear, standardized information about whether scaffolding is safe to use, under construction, or requires maintenance. Without proper tagging systems, workers may unknowingly access unstable or incomplete scaffolding, leading to serious injuries or fatalities.

The color-coded system typically includes:

- Green tags: Scaffolding is complete and safe for use

- Yellow tags: Scaffolding is partially complete or has restrictions

- Red tags: Scaffolding is unsafe and must not be used

Essential Components of an Effective Tag System

Visual Identification Standards

Every scaffold tag must include specific information such as the inspection date, competent person’s signature, maximum load capacity, and any special restrictions. The tags should be weather-resistant and clearly visible from multiple angles. Positioning them at access points ensures no worker can enter the scaffolding area without seeing the safety status.

Documentation and Record Keeping

Maintaining detailed records of scaffold inspections, tag placements, and status changes creates an audit trail that demonstrates regulatory compliance. This documentation becomes invaluable during safety inspections and helps identify patterns that might indicate recurring issues with specific scaffolding configurations or locations.

Integration with LOTO Procedures

Lockout/tagout procedures work hand-in-hand with scaffold tagging systems to create comprehensive safety protocols. While scaffold tags indicate structural safety, a complete LOTO KIT ensures that any energy sources connected to or near the scaffolding are properly isolated and controlled.

Energy Source Management

Construction sites often have scaffolding near electrical systems, hydraulic equipment, or other energy sources. Incorporating LOTO procedures means identifying these hazards and using appropriate devices from your LOTO KIT to secure them before scaffold work begins. This dual approach addresses both structural and energy-related hazards simultaneously.

Implementation Best Practices

Training and Competency Requirements

Every worker who will interact with scaffolding must understand the tag system completely. This includes recognizing different tag colors, understanding their meanings, and knowing the proper procedures for reporting damaged or missing tags. Regular refresher training ensures these critical safety concepts remain fresh in workers’ minds.

Competent persons responsible for scaffold inspection and tagging require additional specialized training. They must understand structural engineering principles, recognize potential failure modes, and make informed decisions about scaffold safety status.

Regular Inspection Protocols

Establishing consistent inspection schedules prevents safety gaps that could lead to accidents. Daily visual inspections by qualified personnel, combined with more thorough weekly examinations, help identify issues before they become dangerous. Weather events, nearby construction activities, or equipment impacts should trigger immediate re-inspection regardless of the regular schedule.

Communication and Accountability

Clear communication channels ensure that tag status changes reach all relevant personnel quickly. When scaffolding transitions from unsafe to safe status, or vice versa, every affected worker must receive this information promptly. Digital tracking systems can supplement physical tags by providing real-time updates and maintaining automatic records.

Common Challenges and Solutions

Weather conditions, vandalism, and normal wear can damage or remove scaffold tags, creating dangerous information gaps. Regular tag maintenance and replacement protocols address these issues proactively. Having backup systems, such as digital records accessible through mobile devices, provides additional safety redundancy.

Worker compliance sometimes presents challenges, particularly when project schedules create pressure to bypass safety procedures. Strong leadership commitment to safety, combined with clear consequences for non-compliance, helps maintain consistent adherence to tagging protocols.

Conclusion

Implementing a comprehensive scaffold tag system requires commitment, training, and consistent execution, but the investment pays dividends in worker safety and regulatory compliance. When properly integrated with LOTO procedures and supported by quality safety equipment, these systems create robust protection against construction site hazards. Safety House Loto remains committed to providing the tools and expertise necessary to maintain the highest safety standards on construction sites. Remember that every tag represents a life potentially saved through proper safety communication and hazard control.

Lockout Tagout And OSHA

Posted On: February 3, 2016

Categorized In: Lockout/Tagout

Written By: Lockout India

At Safety House (LOTO), we adhere to OSHA (Occupational Safety and Health Administration) guidelines while manufacturing lockout tagout/ workplace area safety/ site management products. Our range of products includes key cabinet, This blogpost would give you an insight into what OSHA is, and why following it is imperative for the safety of your employees. lockout supplier

The main federal agency of the US Department of Labor, OSHA was established in 1971 by the Congress under the Occupational Safety and Health Act. The mission of the agency is to “assure safe and healthful working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education and assistance”.

OSHA’s health and safety standards are aimed at preventing accidents and accidental use of energy. The federal agency enforces the development, documentation, implementation, and enforcement of energy control procedures. It recommends that only lockout/ tagout devices authorized for a particular machinery or equipment are used, and that these devices are durable, standardized and substantial. It also asks to ensure that lockout tagout devices identify individual users. OSHA further recommends the establishment of a policy that permits only the employee who applied a LOTO device to remove it. Energy control procedures need to be inspected at least annually. Furthermore, effective training is to be provided for all employees.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now

Lockout Procedures to Follow

Posted On: January 19, 2016

Categorized In: Lockout/Tagout

Written By: Lockout India

Lockout means shutting out machines. An industrial machine shuts for maintenance and servicing activities. It is carried out as a safety measure. The maintenance workers might injure themselves by their sudden startup. There is a certain lockout procedure implemented during the whole process. This process is undertaken by following every known guideline as given by OSHA.

As Lockout India creates safety equipment for such processes, we believe that you, our beloved readers should have an idea of the procedures followed during the process. Please note that the steps we are about to mention are general guidelines or sample steps. In reality, something very close to them is followed because admit it, “field work is much different”.

We need to understand 3 main criteria’s while learning the procedure.

- System – refers to the machines/equipment

- Authorized Employee – refers to the expert who carries out the full procedure

- Affected Employee – includes the workers, various staff members etc. who aren’t qualified to carry out the process

Lockout Procedures

Shutdown

1. The first step is to turn off all the energy sources from the operator’s panel. However, the authorized employee has to make sure that none of the affected employees are still operating as sudden power loss could lead to major accidents.

2. After power shut, notifying the affected employees is the next step. They are to leave their stations immediately and await further instructions.

3. The third step now is to shut down the whole system using normal stopping procedures like powering down, stoppers etc.

Lockout/Tag out

1. Firstly, isolate the system from any energy source. This process is called energy isolation.

2. Lockout and Tag out the system with appropriate safety products.

3. Release any stored energy from the springs, capacitors, hydraulics etc. This is very important as the residual energy in these parts could release automatically during maintenance and harm the crew.

4. Confirm that isolation has actually taken place by trying the equipment.

5. If system doesn’t start means it’s in lockdown mode.

Maintenance

Let the crew carry out maintenance and servicing.

In the meantime, continue your verifications through inspections, observations and tests.

Restarting the System

- After maintenance, remove all the locks and tags.

- Clear out all personnel and unnecessary items from the area.

- The main system shall be then restarted.

- Check whether all machines are working as they should.

- Finally, notify all the employees to resume their work.

One main thing to be kept in mind is that sometimes the work scale is too big meaning multiple authorized employees are involved. However, the procedure is more-or-less ‘the same’. It is unfortunate to say that despite several listed Lockout Tag out procedures, every year thousands of work infringements take place due to non-compliance of appropriate protocols. We, thereby urge all those who are reading this and work in the industry to go through the guidelines provided by OSHA in detail. In case you need further help regarding Lockout Tag out and safety-insured products, ping us!

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Kit

Enquire Now