Elements Of OSHA’s Lockout-Tagout Standard

The elements of Osha Lockout Tagout Standard (29 CFR 1910.147) is a 4-page general industry standard, which was first published in 1989. It was formulated with the single aim of preventing accidental startups of machineries and equipments during their maintenance or service. It lays importance on isolating hazardous energy sources and rendering them isolated. The energy sources include hydraulic, thermal, electrical (stored and active current), chemical, gravitational force, pneumatic and mechanical.

A lockout/tagout program includes 3 basic elements:

1. Written Procedures: These written procedures communicate important information workers involved in lockout/tagout procedures and identify what needs to be done and when. They also prescribe the processes of shutdown, isolation and applying and removing lockout/tagout. Such procedures are only needed for machineries with 2 or more energy sources.

The following should be clearly specified:

– Specific machineries and their shutdown/isolation processes

– Where the lockout devices are installed

– How to de-energize stored energy

– How isolation needs to be verified

2. Training Programs: Training is mandatory for two types of employees, namely authorized employees and affected employees, where the former the people who maintain and service machineries and are qualified enough to control hazardous energies, and the latter are those work in close proximity to the machines/equipments being serviced or repaired under lockout/tagout and need to understand the hazards involved.

3. Timely Audits: Periodic audits ensure that the energy control procedures continue to be correctly implemented, the workforce do not deviate from the procedures and are familiar with their responsibilities. It must take place at least annually. These are also helpful in correcting procedural inadequacies.

Basic steps to lockout/tagout program:

1. Preparation – Think and Plan: Think through the entire procedure. Identify the energy sources that must be controlled and the methods which would be used.

2. Communicate and Notify: The authorized personnel needs to communicate the following to the affected employees:

– The machine that would be locked out and why

– How long will the process take

– Name of the employee responsible for lockout

– Who needs to be contacted for further information

3. Neutralizing the Equipments: It involves disconnecting the electricity, blocking the movable parts, releasing the spring energy, draining or bleeding hydraulic/pneumatic lines and lowering the suspended parts to rest positions.

4. Locking Out: Use lockout devices specific to the machinery. There should be as many locks as the people involved in the process and each person should have a personal lock and key placed on the machinery. Further, it should be noted that locks can only be unlocked by those who installed them.

5. Tagging Out: Tag the machineries, controls, and suspended parts. Tags should also include the contact details of and reasons for locking out.

Verify: Before you continue further, verify if the setup is completely locked out or not.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Importance of OSHA’s Lockout/ Tagout Standards

OSHA (Occupational Safety and Health Administration) is a U. S. Government office entrusted with shielding and directing exercises in the working environment. As a major aspect of the U. S. Work Department, they are in charge of implementing well being and well being benchmarks in each area of business and industry. The directions they have instituted particular to ‘Lockout/Tagout’ are intended to ensure faculty dealing with stimulated hardware for the reasons for set up, adjusting and upkeep.OSHA Lockout Tagout Standards

There are particular enterprises that either are essentially not secured nor have their own particular principles on lockout/tagout for the purpose of warehouse safety:

• While there are other OSHA principles that apply for electrical stun and consume danger, the general standard does not matter to electrical risks from work on, close, or with transmitters or gear in electric use (start wiring) establishments, which are laid out by Subpart S of 29 CFR Part 1910.

• Controlling risky vitality in establishments for the selective reason for power era, transmission, and appropriation, including related gear for correspondence or metering (these sorts of establishments are secured by 29 CFR1910.269).

• Agriculture, development, and oceanic enterprises or oil and gas well boring and overhauling are not secured by the OSHA general standard on lockout/tagout.

The safety programs require significant investment a composed program, including gear particular methods must be established and representatives must be prepared and cash an adequate number of vitality detaching gadgets, (for example, locks) must be acquired and kept up and is regularly observed as badly designed. Therefore, a few managers will attempt to fit a circumstance into an exemption trying to work around the LOTO products and devices for direction since they would prefer not to manage the time, exertion, and burden. In any case, these programs anticipate the occurrence of chances frequently bringing about funds in specialists’ pay costs much more than that of the lockout/tagout program-and spares lives. On the off chance that a machine or bit of gear really does not should be stimulated amid adjusting or support, it ought to be bolted out.

A bolt out gadget is intended to physically cripple a bit of gear absolutely, in this manner keeping its inadvertent operation. These can be as switches on an electrical board or chains and bolts on a valve. Pins, key-squares and wedges are altogether utilized as a part of various applications. Just particular locking systems ought to be utilized on particular bits of gear. Where physical lockout is impractical, a tagout framework will give visual cautioning with regards to the threat display. They will regularly clarify the reason a specific machine is out of administration and demonstrate the person(s) in charge of playing out the important upkeep. Labels are just used to give data and are not a suitable substitute for a locking instrument, if locking is conceivable.

Inability to initiate and take after a compelling Lockout/Tagout program can open laborers to genuine damage and even demise. Numerous wounds have been avoided by appropriately taking after these vital rules. The vast majority of it is judgment skills. Like the directions going with any electrical apparatus in your home, the best exhortation is to “separate from the power before adjusting”.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Common Yet Useful Lockout Devices

1. Circuit Breaker Lockout Devices: These are automatic electrical switches that are designed to protect circuit boards from overload or short circuit. At Lockout India, circuit breakers are designed to work on most varieties of breakers including single-pole and multi-pole breaker specifications.

These are used to isolate a given breaker in a panel so there’s no further need to lockout the entire breaker. Molded from durable plastics, their basic task however is to detect faulty conditions and automatically open the circuit.

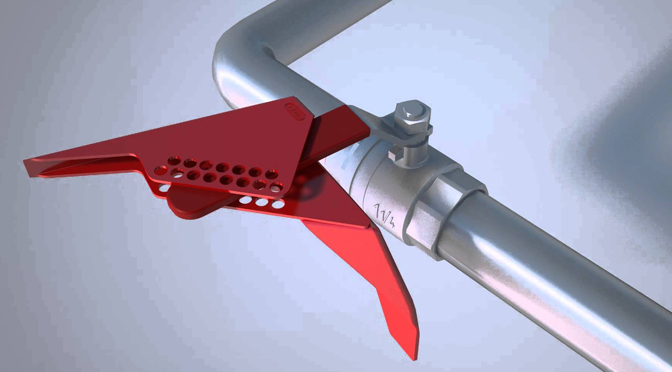

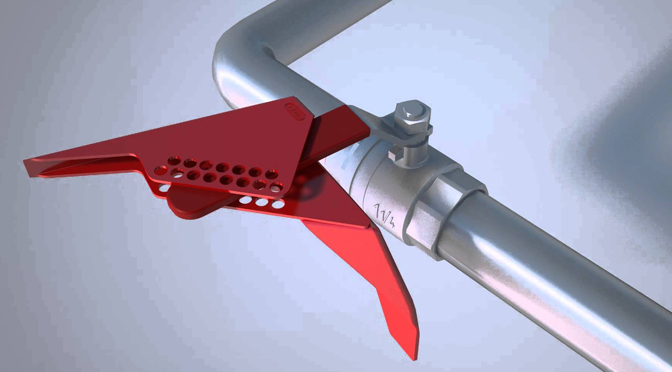

2. Valve and Pneumatic Lockout Devices: Just like electricity, gases and fluids can be significantly hazardous. They tend to move at tremendous pressures and can severely injure if released inappropriately. Valve lockout devices are designed to isolate such hydraulic energy sources. There are different types of available valves such as ball valves, butterfly valves, gate valves, and pneumatic disconnects.

3. Plug Lockout Devices: Portable cords and connected plugs are a common site in work facilities. However, it is important to isolate such electrical sources into a socket using a power plug if one needs to comply with OSHA’s standards.

Our secure design locks onto prongs to prevent them from getting inserted into wall outlets. It can be used with your existing lockout hasps and padlocks.

4. Cable Lockout Devices: This device secures, holds, and locks out electrical power handles and gate valves. Cable lockout devices are conveniently isolated energy and are easy to use. They further ensure successful lockout across multiple energy sources and stop the workforce from actualizing devices while the maintenance is being carried out.

5. Lockout Hasp: Hasp lockout devices are an integral part of a successful safety program. They provide multi-person lockout and multiple padlocks can be applied hasps, allowing the energy to be isolated by more than one worker at a time.

Energy cannot be worked upon until each worker unlocks the padlock. Our wide range of hasps includes dielectric hasps, dual jaw hasps, electroplated hasps, labeled hasps, premier lockout hasps, and non-conductive hasps.

When are these devices used?

– While machinery is being serviced or maintained

– While installing new equipments and machineries

– When a safety device needs to be bypassed or removed

– Moving machineries and equipments

– Any machinery prone to unexpected start-up

Most importantly, whenever a lockout safety device is applied to a machinery, it must remain under exclusive observation and shouldn’t be removed by any unauthorized personnel. manufacturer of lockout products

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

Enquire Now

Also read: How to Use Electrical Lockout Devices and Equipment?

Also read: Types of Lockout Tags & Its Usage for Industrial Safety

Electrical Panel Lockout Switches With Safety

Electrical Panel as the name suggests are the systems which distribute the units of electricity to various electricity circuits due to which the other name is given to electrical panel that is distribution board. These panels are in robust in construction, rectangular in shape and vary in sizes according to the type of system which is to be imparted in the organization. When these Electrical panel lockout are not in use from the safety point of view lockout devices are used to avoid any miss happening to take place or any accident to occur which may lead to sudden death of any individual due to electrical shocks.

The Lockout devices that are very common now days and used in many industries for the purpose of safety are being described in the information stated below.

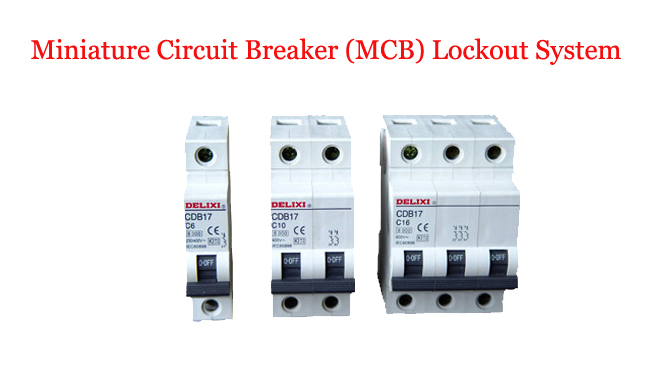

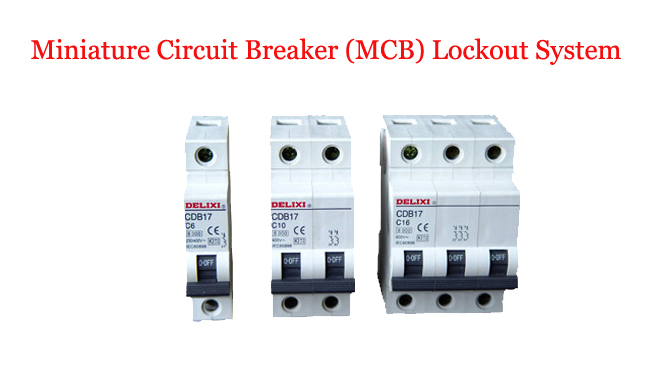

(1) MCB (Miniature Circuit Breaker) / Circuit Breaker Lockout Device very common lockout device, prevents the circuit breaker toggle from being turned on. It is then fit with an appropriate padlock to prevent unauthorized removal.

(2) Electrical Panel Lockout Device as the name suggest device with tough, lightweight, dielectric thermoplastic bodies that completely enclose the electrical plug thus protecting against accidental reconnection.

(3) Pendant Lockout device is used to lock large electrical connectors and control the hoist.

(4) Electrical Panel Lockout is used on switches where there is no inbuilt lockout provision. They consist of removable push button and rotary switch covers, which is secured with a padlock or hasp and this cover prohibits access to a switch or control on the electrical panel. They use transparent bases and cover that allow visibility of nameplates and labels.

(5) Panel Lockout is rectangular strip which is attached to the panel cover and the rectangular strip is encapsulated by the device preventing the panel cover from being removed. The circuit breakers remain locked off while work is being done. The Panel Lockout comes with a brass padlock and reusable tagout. Panel Lockout can also be used to prevent accidental shutdowns of critical equipment by keeping unauthorized persons from accessing electrical circuit breaker panels, security panels, and data centre panels and associated pull boxes.

(6) Electrical panel lockout with square base these are covering provided on the electrical button which is spring operated, these are used to avoid accidentally pressing the button.

The Lockout Tagout Products are a great way to ensure the workplace safety of the organizations as well as the individuals. There are many world pioneers in lockout/ tagout items and administrations that offer a wide scope of strong, simple to-utilize lockout gadgets that cover most mechanical and electrical applications. Many of them cover the other basic parts of an agreeable, viable vitality control program by giving imaginative answers for preparing workers, making reported methodology, and recognizing vitality sources. Many of these devices help various kinds of organizations with restricted assets rapidly get their program up to speed, guaranteeing that lockout exercises are executed in a way that advances ideal well-being while augmenting productivity and lessening downtime.

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- Lockout Hasp

Enquire Now

All About Ball Valve Lockout Devices

A work facility is an inexhaustible source of hazardous energy. Energy sources include electrical, hydraulic, mechanical, pneumatic, thermal, etc. and can be detrimental to work forces within the premises. A lot of industrial mishappenings around the world are caused by unexpected energy release and unanticipated equipment startup.ball valve lockout devices

A lockout safety method locks out such energy-isolating devices and ensures that they cannot be operated until the lockout device is removed. It simply aims at improving safety, maintaining compliance and encouraging sustainability. However daunting it might seem, it’s imperative that all the layers of the organization work towards implementing a sustainable lockout safety program. Without seamless cooperation, a lockout system would fall apart.

Of all the safety Lockout Tagout Products, today, we’ll discuss about Ball Valve Lockout. Ball Valve is a quarter-turn, straight-through valve that suitably transfers liquids, compressed air, clean gas and slurries (liquids with suspended solids). It uses a hollow and perforated ball to control the flow through it. The ease of operation, repair and versatility that comes with ball valves is what leads to its extensive industrial use. Ball valves have a round closure element that permits consonant sealing stress. Getting its name from the ball that rotates within to close and open the valve, these devices are used where a taut shut-off is required and are a fine source for control applications. Durable and reliable even after jagged use, these safety devices are often preferred to gate and globe valves. Ball valves involve the use of materials such as nylon, delrin, synthetic rubbers and polymers and that imparts an excellent sealing ability. However, there is a potential of wear on the seats and it renders it unsuitable for throttle applications.

Types of Ball Valves:

Valve operation in each type remains the same. The only difference is how these valves are manufactured and assembled. Each design has its own benefits.

– Split body Ball Valve

– Top entry Ball Valve

– End entry Ball Valve

– Double trunnion Ball Valve

– 3-piece Ball Valve

– Lubricated/Non-lubricated Ball Valve

Advantages that a ball valve renders:

– Smooth and straightforward actuation

– Swift opening and closing

– More compact and lighter than a gate valve

– Bubble-tight service

– Wide choices, thus allowing flexibility

– Multi-port designs

– Reliable in high-temperature and high-pressure applications

Used in a variety of applications such as gas processing and storage, fire safe protection services, chlorine manufacturing, and flowing systems, ball valves. Some typical applications are:

– Low point drains in fluid services

– High-point vents in fluid services

– Instrument root valves

– Steam service

– Feed water systems

At Lockout India, it’s all about committing to quality, performance and service. We are the leading manufacturer of various types of Ball Valve Lockout devices and our products satiate different industrial requirements and convincingly control the flow of diverse gases and fluids.

Checkout Our Other Lockout Tagout Products:

- Lockout Kit

- Group Lockout Box

- Lockout Station

Enquire Now

Keeping the work facility safe: A guide for employers

General industry workers who service and maintain the machineries are exposed to unexpected energization, startup and release of hazardous energy. The work practices can prove to be fatal if proper safety measures aren’t followed. This is where OSHA heavily focuses. OSHA’s standard 1910.147 is all about the control of hazardous energy (lockout/tagout) and requires energy control procedures for all the machines that are prone to dysfunction and could be a source of mechanical/chemical/thermal/hydraulic energy outburst.

Who has the ultimate responsibility to implement lockout safety procedure within a facility? This is perhaps the most-asked question. OSHA requires the employers to take proper steps against unexpected machinery startup and energy outbursts. But simply buying the Lockout Tagout Products is not enough. Most of the firms fall short on enabling effective procedures and fast action by employees. They do not have a set of machine-specific instructions and these instructions are generally not handy to the employees.

Follow the below mentioned steps and ensure a consistent and effective lockout safety program:

– Communication is the key: Communicate to your employees the benefits of an effective lockout program. It is your duty to instill in your employees the value of a safe working environment. Also, produce an easy-to-use set of guidelines that your employees understand.

– Make a complete list of machinery that might require lockout safety procedures. It is also important to keep your equipments in a healthy state with timely maintenance and repairs.

– Identify the energy points and label the isolation devices (valves and breaker panels).

– List and document the hardware that might be needed for to lock out and isolate machinery and equipment. Devices such as padlocks and tags.

– There’s no generic safety procedure. Make sure you document machine-specific procedures and specific steps to isolate, secure and shut it down.

– Implement comprehensive training sessions and make sure the employees have a clear understanding of safety procedures and the magnitude of hazardous energy sources within the facility.

– Sort out your workers according to their lockout responsibilities. Anyone unaware of the health hazards and safety procedure shouldn’t be allowed near the machineries but still must receive basic instructions regarding energy control. As an employer, it is your responsibility to protect all the workers.

And lastly, keep reviewing and updating your safety program. Just like machinery, a lockout safety program requires periodic reviews.

Checkout Our Other Lockout Tagout Products:

- Valve Lockout

- MCB Lockout

- Lockout Padlocks

Enquire Now

Miniature Circuit Breaker (MCB) Lockout System

A fuse, as we all know, needs to be replaced once operated. These days, most of the circuits come with an alternative and that is a Miniature Circuit Breaker (MCB). An MCB Lockout is an electromagnetically device which operates as an automatic switch and protects an electrical circuit from damage caused by excess current or overheating, generally caused by a short-circuit or a faulty design. Unlike a fuse, when an overload is detected, an MCB doesn’t have to be replaced. It can be reset, either manually or automatically and continue to function and thus offers an improved functioning and operational safety without additional costs. In a nutshell, an MCB functions as a switch that automatically turns off when the flowing current passes the allowed limit.

A miniature circuit breaker comprises of two contacts, fixed and moveable. A solenoid forces the moveable contact to disconnect from the fixed one whenever the current exceeds the allowed limit, thereby stopping the current flow through the circuit. This mechanism protects from current over load. However, a bi-metallic strip is used to protect from overheating and increase in temperature. The overload causes the temperature to rise and subsequently, the bi-metallic strip heats and deflects. The deflection then releases the trip latch and separates the contacts.

Miniature circuit breakers serve two purposes. They function as a fuse and as a switch. By toggling the switch to the ‘off’ position, the circuit can be opened for safety and maintenance purposes. Before the maintenance process begins, miniature circuit breakers need to be locked and tagged out. This ensures that they are not accidentally reactivated while maintenance is still in process.

While there are numerous companies dealing in lock out devices, Lockout India manufactures safe, effective and reliable universal miniature circuit breakers lockout devices that work on most circuit breakers throughout the world. They comply with OSHA’s safety standard 1910.147 and ensure that electrical energy sources are locked out for optimum work safety. These lockout devices are manufactured using durable plastics and effectively lock out the circuit breakers. These can be used for single, double, triple and quadruple pole MCB and can be easily installed using a screwdriver.

Checkout Our Other Lockout Tagout Products:

- MCB Lockout

- Lockout Padlocks

- Scaffold Tag

Enquire Now

Safety House Loto Products For Safe Work Environment

What is a Lockout/Tag out?

The logout/tag out is abbreviated as LOTO these are practices and procedures are now a days a very common practice which means shutting off the dangerous machines which contains hazardous waste like lubricating oils, smoke and degradable products which may harm the environment and not able to start them until and unless completion of maintenance or servicing work is done.Safety House Loto Products

While servicing is done hazardous energy is isolated and inoperative because if this hazardous waste is let free in the air might create a severe problem. After the service is done the service man hen locked and a tag is placed on the lock identifying the worker who has placed it which again states that this practice is a useful and safe practice for both the employee and environment as well. There are special devices designed and applied according to the nature of hazardous energy and nature of use which does not allow disposing of this hazardous waste into the open air. All these devices have the main motive of ensuring the workplace safety of all the individuals who are working under the organization.

There are various kinds tag out devices which can be used depending on the needs and interests of the hiring organizations and firms. Below stated are some different types of lockout devices with the name and nature of its use.

(1) Adjustable Ball valve locks are the most prominent devices used now a days in industry because they are easy to install and does not allow the easy disposed off the fluids nature of molecule as the application is the most simplest of all the tag out devices.

(2) Valve Lockouts are kind of caps which are placed on the rotating type valves, these are very easy to install and effective when in use.

(3) Safety Locks as the name suggest are the simple locks used at the storage areas where the hazardous waste is kept off to lock some operating rooms which are not in use of a room where the entry in only done when a person is able to fulfil the safety parameters as per required.

(4) Hubell Plugout used where the wires with plugs in front and the wires are not in use for some time. These are used to avoid the damage of the plug and as the material of the plug are plastic which may lead to damaging the environment as well.

(5) Circuit breaker lockout as the name suggest these are used where the electrical panel is installed and these helps in achieving operator safety.

Conclusion

There are many more which can be used but some of the basic tag out or lockout devices for the workplace safety are jotted down in the information stated above. Hence, we can conclude by remarking that the tag out devices can be used for the betterment of the environment of any organization as well as the proper safety of the employees working in that particular firm too.Safety House Loto Products

Checkout Our Other Lockout Tagout Products:

- Valve Lockout

- MCB Lockout

- Lockout Padlocks

Enquire Now

Never Ignore Workplace Safety

If we say that a belonging can come in a working environment that can only be achieved or attained by keeping the employee safe, if a employee is not safe or does not have safe working environment he/she will never be happy will not religiously work for you and may commit mistakes while working, the mistake can go up to that extent that a working operator can meet with a sever accident and can lead death. Workplace Safety

Definition of Safety

Safety as the word suggest means creating safe working environment like having sufficient amount of light while doing so critical work, optimum exhaust openings while doing some job which may include use of hazardous effluents, use of gloves while working on machines, use of helmet when working on height, wearing shoes when in workshops. Ergonomics is also considered as one of the most important part of occupational health and safety as a proper layout is made and the execution is laid accordingly helps in reducing the chances of workers fatigue. This applies not only to those working on computer workstations but also to those using equipment which are controlled from one place. The principles of ergonomics apply to all workers who spend hours sitting in the same position.

There is one procedure called LOTO (Logout/Tagout) which means no equipment containing hazardous will be back into proper functioning until and unless the hazardous waste has been properly disposed off. These regulations highlight the employer’s responsibility to protect workers from hazardous energy sources, with managers encouraged to develop safety programs that are best suited to their facility. There are many kinds of the Loto Products which help in maintaining the workplace safety for the organization as well as that of the employees of the organization but also in ensuring the ignorance and prevention of various mishaps.

The application of these devices is most common in pipelines where the use of valve is frequent.

(1) Adjustable Ball Valve lockout are the locks fitted on the handles to avoid the escape of the hazardous fluids from the pipe lines.

(2) Valve locking covers are used on the valve having handle made of round shape. These are used to avoid the twisting of the handle of the valve and avoid the flow of the fluid containing element that can harm the environment.

(3) Locks and key safety systems are the system applied where there is a separate room to keep the hazardous waste and used in operating rooms as well as used in FMGC units where safety is considered the top most requirements.

(4) Circuit Breaker locks are used to avoid any accident related to electricity and used where there is complete shut down in the plant.

(5) Hubbell Plugout is the types of locks used particularly on wire having chords attached to it. Chords are nothing but special plug attached to wire to make connection in some electronic devices. The plug outs are used to cover these chords so that the chords are not broken and damaged due to any means as the material used to make chords in plastic which is very harmful for environment as it non bio degradable product.

Conclusion

In all, the loto products with time have proven to be great supporters and helpers when it comes to the safety of the firm and its people. The use of such products should be on a higher note for the sake of individual safety because nothing is more important than the health and safety of any individual be it a worker or the owner of the enterprise. Workplace Safety

Checkout Our Other Lockout Tagout Products:

- Scaffold Tag

- MCB Lockout

- Lockout Padlocks

- LOTO KIT

Enquire Now